With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Applications

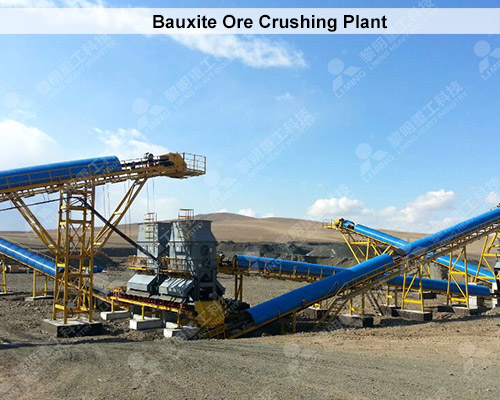

Bauxite Ore Crusher

Bauxite Crushing Challenges in Alumina Refining

Bauxite ore (Al(OH)₃/AlOOH) requires careful size reduction to:

- Produce 3-30mm feed for Bayer digestion

- Minimize -1mm fines causing red mud issues

- Handle high-clay content (up to 25%)

Liming Heavy Industry designs Bauxite Ore Crushers with patented anti-clogging technology for lateritic and karst-type deposits.

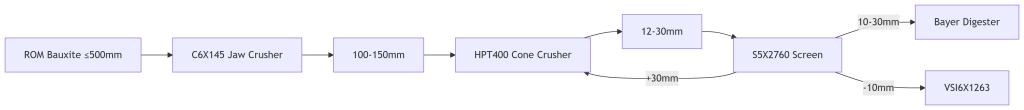

Stage 1: Primary Crushing – ROM Ore Reduction

- Challenge: Breaking soft but abrasive ore with high moisture (15-30%)

- Solution:Jaw Crushers with wedge-block discharge

Liming Equipment:- C6X Series Jaw Crusher (e.g. C6X125)

- ≤430mm feed size for Guinean bauxite

- T-shaped discharge slot prevents clay buildup

- PE Series Jaw Crusher (e.g. PE900×1200)

- ≤150mm output with <8% -3mm fines

- C6X Series Jaw Crusher (e.g. C6X125)

Stage 2: Secondary Crushing – Size Optimization

- Challenge: Achieving 10-30mm ideal digester feed

- Solution:Multi-cylinder Cone Crushers with hydraulic clearing

Liming Equipment:- HPT Series Cone Crusher (e.g. HPT300)

- Anti-clogging concave design

- 0-30mm adjustable output

- HST Series Cone Crusher (e.g. HST250)

- ≤25mm cubicle product

- HPT Series Cone Crusher (e.g. HPT300)

Stage 3: Clay Processing – Specialized Solutions

- Challenge: Separating embedded clay lumps

- Solution:Impact Crushers with material scrubbing

Liming Equipment:- VSI6X Sand Maker (e.g. VSI6X1263)

- Rotor impact anvil disintegrates clay

- 40% less moisture retention

- LUM Ultrafine Mill (For kaolinite byproduct)

- VSI6X Sand Maker (e.g. VSI6X1263)

Integrated Processing Systems

- S5X Vibrating Screen (e.g. S5X2460-3)

- Rubber-coated decks for wet screening

- B6X Belt Conveyor

- Self-cleaning scraper for sticky material

Technical Advantages for Bauxite Applications

| Feature | Benefit |

|---|---|

| Patented Anti-Clogging | Zero downtime in 25% clay ore |

| Ceramic Wear Liners | 3x lifespan vs chrome steel |

| Variable Frequency Drive | Adjustable fines ratio (5-15%) |

| Modular Screen Decks | Quick switch: gibbsite ↔ boehmite |

Plant Configuration (Guinea 3,500TPH Project)

Performance Data:

- Ore Type: Lateritic bauxite (SiO₂ 8%)

- Final Product: 88% 10-25mm

- Clay Moisture Reduction: 22% → 16%

Why Global Alumina Producers Choose Liming

“Over-crushing bauxite increases red mud by 18% – our HPT system maintains <12% -1mm fraction at 3,800TPH.”

– Liming Bauxite Process Engineer

Tailored Solutions for:

- Tropical Laterites: Mobile K3-2385 Plant with clay scrubber

- Hard Diaspore Ores: HPT + HST circuit

- Refractory Grade Bauxite: VSI6X shaping for calcination

Free Bauxite Test Crushing:

→ Submit 100kg samples for abrasion/fines analysis

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

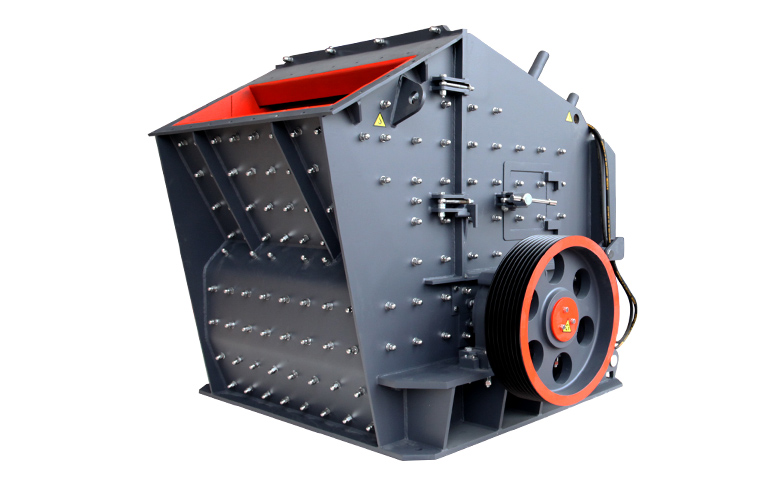

PFW Impact Crusher

Mining & Quarrying: Efficiently crushes ores (gold, iron, copper) and aggregates. Construction: Processes limestone, concrete, and demolition waste for road/base materials. Recycling:.

Learn More

HPT Hydraulic Cone Crusher

Mining & Quarrying: Crushing hard rocks (granite, basalt, iron ore) with high reduction ratios. Aggregate Production: Producing cubic-shaped end products for construction.

Learn More

PE Jaw Crusher

Ideal for primary crushing of various materials: Mining/Ore Processing: Crushing gold, copper, iron ore, and manganese. Aggregates & Construction: Granite, basalt, limestone,.

Learn More

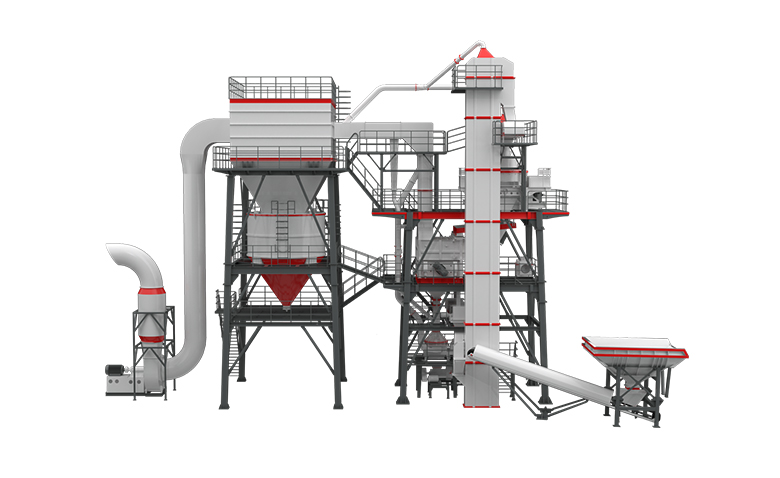

VUS Aggregate Optimization System

Sand & Gravel Production – Produces high-purity machine-made sand for concrete, asphalt, and dry-mix mortar. Sludge & Tailings Recycling – Recovers fine.

Learn More

PF Impact Crusher

Mining: Crushing iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregates: Processing limestone, granite, concrete, and construction waste for road/base.

Learn More

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More