With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Applications

Lead-Zinc Ore Crusher

The Critical Crushing Process in Lead-Zinc Beneficiation

Lead-zinc ores (primarily galena PbS and sphalerite ZnS) require precise size reduction to liberate valuable minerals while minimizing overgrinding. As a global manufacturer of mineral processing equipment, Liming Heavy Industry engineers Lead-zinc Ore Crusher that deliver optimal particle size distribution for flotation efficiency.

Stage 1: Primary Crushing – ROM Ore Reduction

- Challenge: Hard, abrasive ores with unconfined compressive strength (UCS) up to 180 MPa

- Solution: High-torque Jaw Crusher with deep crushing chambers

Liming Equipment:- C6X Series Jaw Crusher (e.g. C6X125, C6X160)

- Eccentric forged shaft for ≤400mm feed size

- 20% longer service life in sulfide ore applications

- PE Series Jaw Crusher (e.g. PE900×1200)

- Wedge adjustment for 75-200mm output

- C6X Series Jaw Crusher (e.g. C6X125, C6X160)

Stage 2: Secondary Crushing – Particle Shape Optimization

- Challenge: Producing cubical particles (15-50mm) to prevent flotation reagent waste

- Solution: Multi-cylinder Hydraulic Cone Crusher

Liming Equipment:- HPT Series Cone Crusher (e.g. HPT300, HPT500)

- Laminated crushing for complex Pb-Zn-Cu ores

- Automatic iron passing protection

- HST Series Cone Crusher (e.g. HST250)

- ≤25mm product for high-sphalerite ores

- HPT Series Cone Crusher (e.g. HPT300, HPT500)

Stage 3: Tertiary Crushing – Flotation Feed Preparation

- Challenge: Achieving 3-10mm optimal liberation size

- Solution:Vertical Shaft Impact (VSI) Crusher

Liming Equipment:- VSI6X Sand Maker (e.g. VSI6X1263)

- Rotor centrifugal crushing for selective galena liberation

- 45% less slimes generation vs conventional crushers

- VSI6X Sand Maker (e.g. VSI6X1263)

Integrated Auxiliary Systems

- S5X Vibrating Screen (e.g. S5X1860-4)

- Polyurethane screens for 4mm classification

- B6X Belt Conveyor

- Dust-proof design for toxic lead dust containment

Technical Advantages of Liming Lead-Zinc Crushers

| Feature | Benefit |

|---|---|

| Patented Wear Parts | 2.5x lifespan in high-sulfide ores |

| Hydraulic Clearing | Zero downtime for tramp iron removal |

| Intelligent Control | Real-time product size adjustment (±3mm) |

| Modular Design | Quick conversion Pb/Zn → Cu/Mo circuits |

Equipment Performance:

- Throughput: 520 TPH sphalerite-dominant ore

- Final Product: 92% below 8mm

- Wear Part Replacement: 4,800 operating hours

Why Global Mining Operators Choose Liming

“Over-grinding galena increases slimes by 15-30% – precise crushing is essential for Pb recovery.”

– Liming Mineral Processing Engineer

Tailored Solutions for:

- Massive Sulfide Deposits: C6X + HPT circuit with 10:1 reduction ratio

- Oxidized Zinc Ores: Mobile K3-2175 Plant with integrated VSI6X

- Complex Pb-Zn-Ag Ores: Grinding-pre-crushing with HST315 Cone Crusher

Request Ore Test Crushing Service:

→ Submit your ore sample for free size reduction analysis using Liming C6X/HPT/VSI6X crushers.

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

CI5X Impact Crusher

The CI5X Impact Crusher is widely used in: Quarry & Mining Operations – Crushing aggregates, limestone, dolomite, and more Recycling – Processing.

Learn More

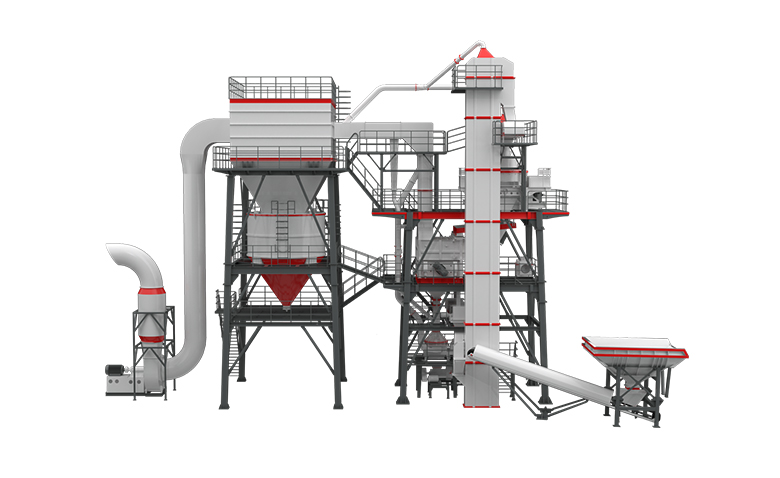

VUS Aggregate Optimization System

Sand & Gravel Production – Produces high-purity machine-made sand for concrete, asphalt, and dry-mix mortar. Sludge & Tailings Recycling – Recovers fine.

Learn More

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More

VSI6X Sand Making Machine

Construction: Produces high-grade sand for concrete, asphalt, and ready-mix plants. Mining: Processes iron ore, gold ore, and non-metallic minerals into fine aggregates..

Learn More

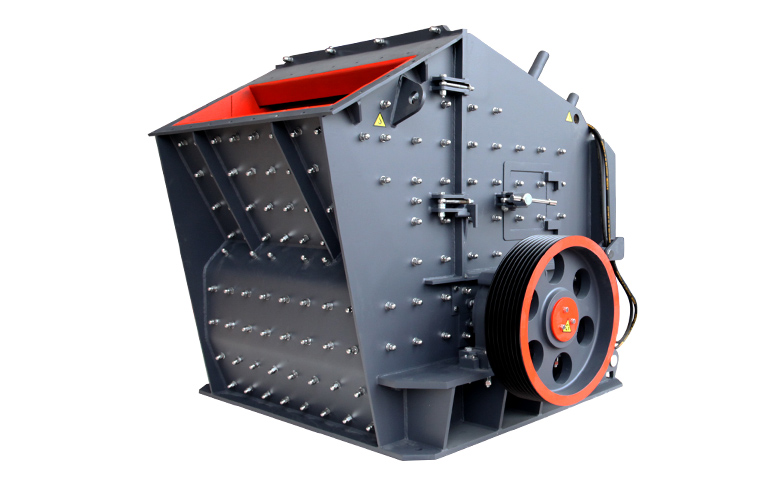

PFW Impact Crusher

Mining & Quarrying: Efficiently crushes ores (gold, iron, copper) and aggregates. Construction: Processes limestone, concrete, and demolition waste for road/base materials. Recycling:.

Learn More

HST Hydraulic Cone Crusher

The HST Hydraulic Cone Crusher is ideal for: Mining: Efficient crushing of ores (iron, copper, gold, etc.) Quarrying: Processing hard rocks (granite,.

Learn More