With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Applications

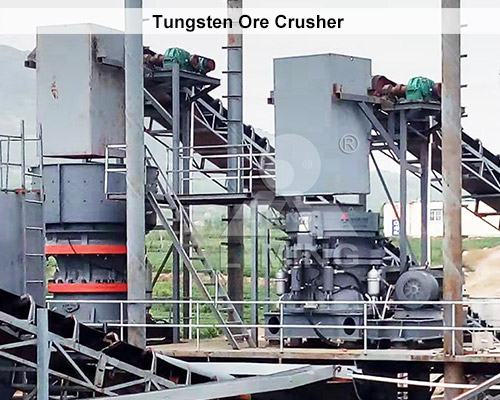

Tungsten Ore Crusher

Tungsten Ore Crushing Challenges

Tungsten ores (wolframite (Fe,Mn)WO₄ / scheelite CaWO₄) require:

- Selective liberation at 2-10mm for gravity separation

- Minimizing slimes (-0.075mm) causing >15% WO₃ loss

- Handling abrasive quartz veins (UCS 250-350 MPa)

Liming Heavy Industry designs Tungsten Ore Crushers with precision closed-side settings (CSS) for complex vein deposits.

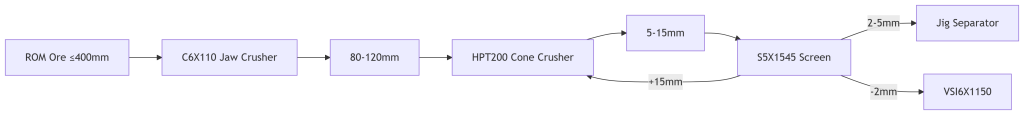

Stage 1: Primary Crushing – Vein Ore Reduction

- Challenge: Breaking hard quartz-wolframite masses

- Solution:Jaw Crushers with reinforced toggle system

Liming Equipment:- C6X Series Jaw Crusher (e.g. C6X110)

- ≤425mm feed for Chinese wolframite ore

- MX14 jaw plates with 2,800+ hours lifespan

- PE Series Jaw Crusher (e.g. PE750×1060)

- ≤100mm output with <5% -3mm fines

- C6X Series Jaw Crusher (e.g. C6X110)

Stage 2: Secondary Crushing – Selective Liberation

- Challenge: Preserving scheelite crystals (1-5mm)

- Solution:Multi-cylinder Cone Crushers

Liming Equipment:- HPT Series Cone Crusher (e.g. HPT200 Fine Cavity)

- Laminated crushing reduces slimes

- 5-15mm adjustable output

- HST Series Cone Crusher (e.g. HST160)

- ≤12mm for scheelite skarn ores

- HPT Series Cone Crusher (e.g. HPT200 Fine Cavity)

Stage 3: Tertiary Crushing – Gravity Feed Prep

- Challenge: Generating 2-5mm jig/spiral feed

- Solution:Vertical Shaft Impact Crushers

Liming Equipment:- VSI6X Sand Maker (e.g. VSI6X1150)

- Rotor speed 1,200-1,800 rpm

- -0.075mm generation <10%

- LUM Ultrafine Mill (For tailings reprocessing)

- VSI6X Sand Maker (e.g. VSI6X1150)

Critical Auxiliary Systems

- S5X High-Frequency Screen (e.g. S5X1545-2)

- 0.5/1/2mm polyurethane decks

- B6X Dust-Proof Conveyor

- Sealed design for WO₃ dust containment

Technical Advantages for Tungsten Ores

| Feature | Benefit |

|---|---|

| Precision CSS Control | ±0.5mm size adjustment |

| Ceramic Composite Liners | Zero Fe contamination |

| Variable Frequency Drive | Slimes ratio control (8-15%) |

| Quick-Release Concaves | 2hr change for HPT series |

Plant Configuration (Bolivia 180TPH Project)

Performance Data:

- Ore: Wolframite-quartz vein (WO₃ 0.8%)

- Final Product: 91% 1-6mm

- WO₃ Recovery Increase: 22% vs conventional crushing

Why Tungsten Miners Choose Liming

“Overgrinding reduces wolframite recovery by 30% – our HPT fine cavity maintains >90% +0.5mm fraction.”

– Liming Mineral Processing Director

Tailored Solutions for:

- Vein Deposits: C6X + HPT circuit

- Disseminated Scheelite: Mobile K3-1385 Plant

- High-Slime Ores: VSI6X + LUM Mill system

Free Tungsten Test Crushing:

→ Submit 50kg samples for liberation analysis

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

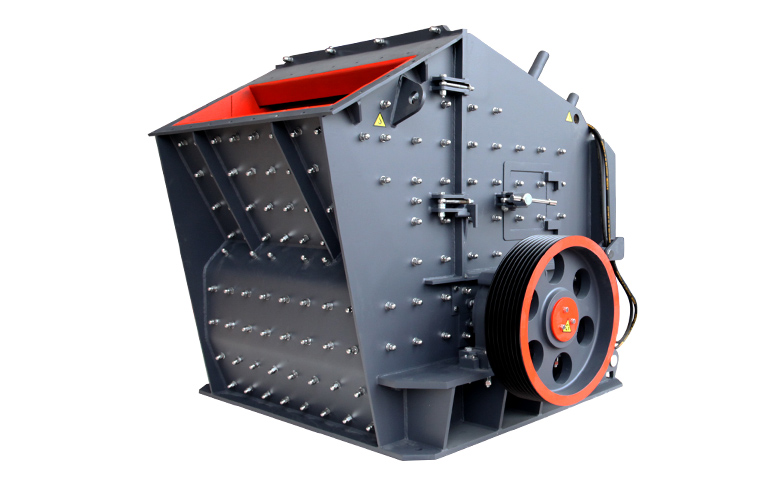

PFW Impact Crusher

Mining & Quarrying: Efficiently crushes ores (gold, iron, copper) and aggregates. Construction: Processes limestone, concrete, and demolition waste for road/base materials. Recycling:.

Learn More

VSI6X Sand Making Machine

Construction: Produces high-grade sand for concrete, asphalt, and ready-mix plants. Mining: Processes iron ore, gold ore, and non-metallic minerals into fine aggregates..

Learn More

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More

C5X Jaw Crusher

Mining & Ore Processing Ideal for primary crushing of iron ore, gold ore, copper ore, and other metallic/non-metallic minerals. Handles tough materials.

Learn More

PE Jaw Crusher

Ideal for primary crushing of various materials: Mining/Ore Processing: Crushing gold, copper, iron ore, and manganese. Aggregates & Construction: Granite, basalt, limestone,.

Learn More

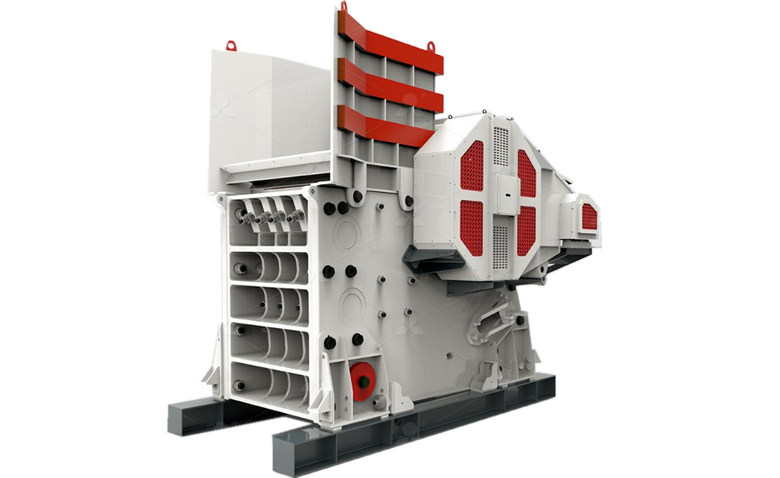

CI5X Impact Crusher

The CI5X Impact Crusher is widely used in: Quarry & Mining Operations – Crushing aggregates, limestone, dolomite, and more Recycling – Processing.

Learn More