Projects

150 TPH Limestone & Basalt Crushing Plant In Ethiopia

Client Profile

Location: Ethiopia

Material: Limestone & Basalt (mixed feed)

Required Output: 150 tons per hour

Final Use: Road construction and building aggregates

Project Overview

An Ethiopian construction company needed a reliable sand and aggregate production line to process local limestone and hard basalt (Mohs hardness 7-8) for infrastructure projects. The challenge was to design a cost-effective solution capable of handling abrasive materials while ensuring <150mm feed size and producing 0-5mm, 5-20mm, and 20-40mm graded aggregates.

Key Challenges

- High basalt hardness causing wear on conventional crushers

- Strict requirement for final product gradation (±5% tolerance)

- Limited local technical support availability

- Dust control in dry processing

Our Solution

Equipment Configuration:

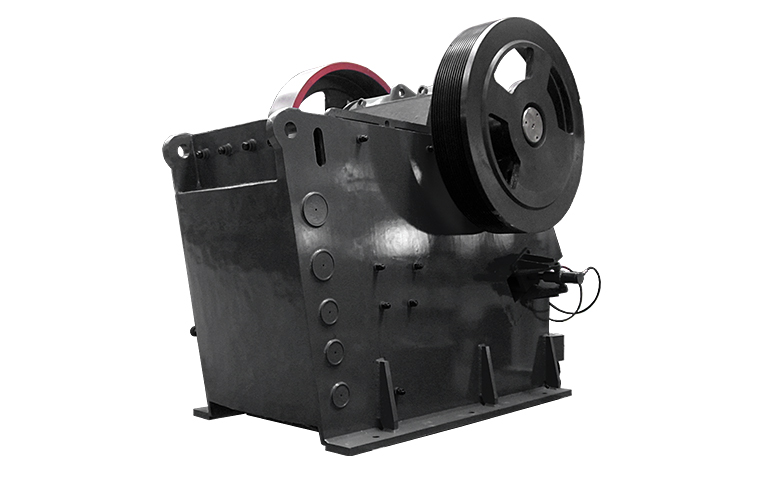

- Primary Crushing:

- PEW1100 European Jaw Crusher

- Handles 1500mm feed size

- Hydraulic adjustment protects against tramp metal

- 30% longer jaw plate life with manganese steel casting

- PEW1100 European Jaw Crusher

- Secondary Crushing:

- HST315 Single Cylinder Hydraulic Cone Crusher

- Processes basalt with ≤5% fines production

- Automatic over-iron protection system

- Laminated crushing principle for cubic aggregate

- HST315 Single Cylinder Hydraulic Cone Crusher

- Tertiary Crushing & Shaping:

- VSI6X1263 Sand Maker

- Produces 0-5mm high-quality manufactured sand

- Oil-free lubrication reduces maintenance

- VSI6X1263 Sand Maker

- Auxiliary Equipment:

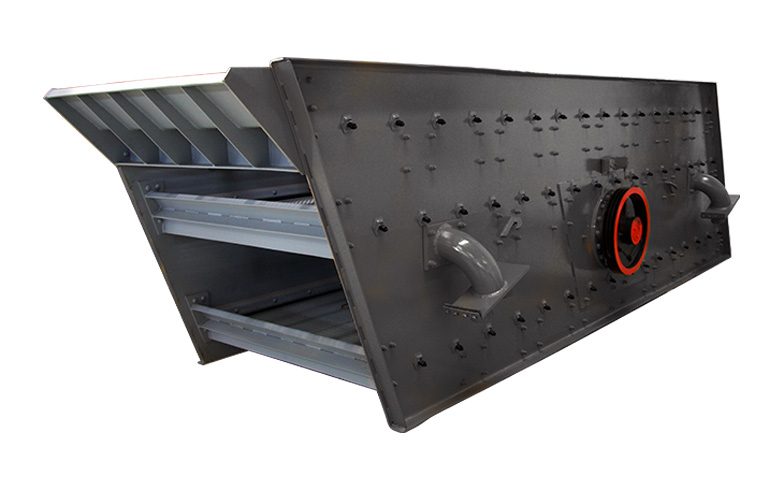

- 3YK3072 Vibrating Screen (3-deck classification)

- ZSW490×130 Vibrating Feeder (15m³ capacity)

- Belt Conveyor System (Dust-proof design)

Technical Highlights

- Smart PLC control system enabling remote monitoring

- Multi-stage dust collection (PM2.5 <30mg/m³)

- Energy-efficient design (0.65kWh/ton power consumption)

- Quick-wear part replacement system (<4hrs downtime)

Project Results

- Output: Stable 158tph production (5% over target)

- Product Quality: 93% cubic aggregate rate exceeding ASTM C33

- Uptime: 94% operational availability in first year

- ROI: Client recovered investment within 11 months

Client Feedback

“Liming’s team designed the perfect layout for our limited site space. The HST315 cone crusher requires no manual adjustment even when switching between limestone and basalt. After 8 months of operation, we’ve had zero unplanned stoppages.”

— Project Manager, Ethiopian Construction Company

Custom Crushing Solutions For All

Mining & Aggregates Needs

while minimizing operational costs through smart, sustainable designs.

Key Equipment

VSI6X Sand Making Machine

PEW Jaw Crusher

YKN Vibrating Screen