With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Projects

150 TPH River Stone Sand Making Plant in Ethiopia

Client Overview

Location: Ethiopia

Material: River stone (200-500mm)

Capacity: 150 tons/hour

Final Products: 0-5mm, 5-15mm, 15-30mm aggregates

Project Challenges

- High hardness of Ethiopian river stones

- Strict requirement for sand particle shape

- Limited infrastructure for equipment maintenance

- Dust control in dry processing

Liming’s Solution

Equipment Configuration

- PE750×1060 Jaw Crusher (Primary Crushing)

- Processes raw 500mm river stones into ≤210mm pieces

- Features rugged structure for abrasive materials

- HST315 Single-cylinder Hydraulic Cone Crusher (Secondary Crushing)

- Further reduces material to ≤60mm

- Automatic overload protection ensures continuous operation

- VSI6X1263 Sand Maker (Tertiary Processing)

- Produces high-quality cubic-shaped sand (0-5mm)

- Lower wear costs compared to conventional impact crushers

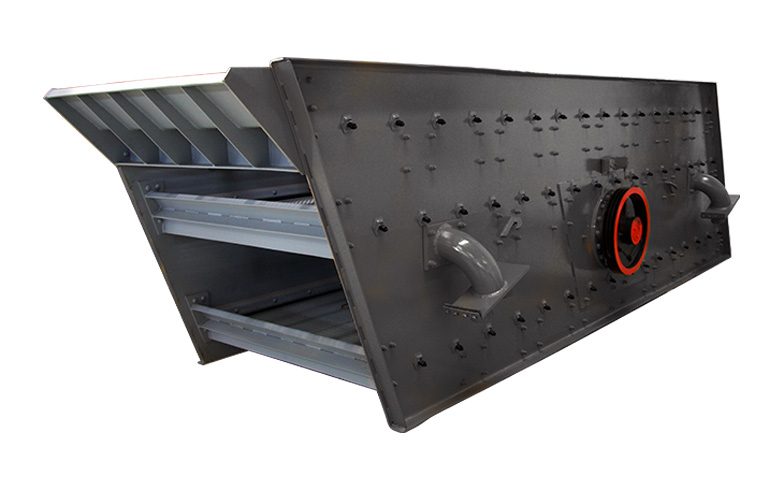

- 3YZS2460 Vibrating Screen (Screening)

- Accurate grading into 3 specifications

- Dust-proof design for cleaner operation

- Conveyor System & Dust Collector

- Belt width: 800mm

- Pulse jet bag filter meets environmental standards

Technical Highlights

- Energy Saving: Tier-3 diesel generator option available

- Modular Design: Quick installation in remote areas

- Wear Resistance: Tungsten carbide parts for extended service life

- Automated Control: Touchscreen PLC system

Project Results

- Achieved 160TPH (surpassing target by 6.7%)

- Sand yield rate: 92% (exceeding local market standard)

- Noise level: <75dB at 1-meter distance

- Operational since 2023 with zero major breakdowns

Client Testimonial

“Liming’s team designed a perfect layout for our limited space. The HST315 cone crusher requires less maintenance than expected, and the final sand quality helped us win concrete supply contracts.”

— Project Manager, Ethiopian Construction Co.

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

PE Jaw Crusher

Ideal for primary crushing of various materials: Mining/Ore Processing: Crushing gold, copper, iron ore, and manganese. Aggregates & Construction: Granite, basalt, limestone,.

Learn More

HST Hydraulic Cone Crusher

The HST Hydraulic Cone Crusher is ideal for: Mining: Efficient crushing of ores (iron, copper, gold, etc.) Quarrying: Processing hard rocks (granite,.

Learn More

VSI6X Sand Making Machine

Construction: Produces high-grade sand for concrete, asphalt, and ready-mix plants. Mining: Processes iron ore, gold ore, and non-metallic minerals into fine aggregates..

Learn More

YKN Vibrating Screen

Mining & Minerals: Ideal for grading coal, iron ore, copper, and gold ore. Aggregates & Sand: Efficiently screens crushed stone, gravel, and.

Learn More