Projects

200-800 TPH Basalt Crushing Line In Yemen

Client Profile

A prominent construction materials supplier in Yemen sought a reliable partner to establish a large-scale basalt crushing line. Their goal was to produce high-quality aggregates for local infrastructure projects, requiring a production capacity of 200–800 tons per hour (TPH).

Project Overview

The client needed a turnkey solution to process hard basalt into multiple sizes of aggregates (0–5mm, 5–10mm, 10–20mm, and 20–40mm) for concrete and road construction. Key challenges included the material’s high abrasiveness, strict output gradation requirements, and limited onsite space.

Challenges

- Material Hardness: Basalt’s high silica content demanded durable crushers.

- Throughput Flexibility: The plant needed to adjust output between 200–800 TPH seamlessly.

- Dust & Noise Control: Compliance with Yemen’s environmental regulations.

- Space Constraints: Compact layout design for efficient operation.

Solution: Liming Heavy Industry’s Crushing Line

Equipment Configuration & Advantages

- Primary Crushing: PE1200×1500 Jaw Crusher

- Role: Coarse crushing of raw basalt (≤1000mm) to ≤300mm.

- Advantage: Deep crushing chamber, high wear resistance, and low energy consumption.

- Secondary Crushing: HST315 Hydraulic Cone Crusher

- Role: Further reduces material to ≤70mm for high-quality aggregates.

- Advantage: Multi-cylinder hydraulic design ensures stable output and low downtime.

- Tertiary Crushing & Sand-Making: VSI6X1263 Vertical Shaft Impact Crusher

- Role: Produces 0–5mm manufactured sand with excellent cubical shape.

- Advantage: German-patented rotor design for 30% higher throughput.

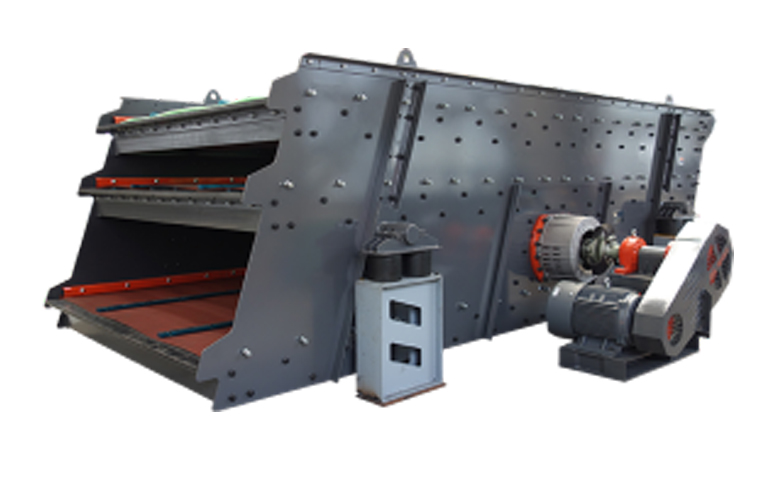

- Screening: S5X3075-3T Vibrating Screen (3 decks)

- Role: Precise classification into 4 final products.

- Advantage: High screening efficiency with anti-clogging polyurethane mats.

- Dust Control: Pulse Dust Collector System

- Role: Reduces airborne particles below Yemen’s permissible limits (PM10 ≤50mg/m³).

Technical Highlights

- Smart Control System: PLC automation for real-time production adjustments.

- Energy Efficiency: 15% lower power consumption vs. industry standards.

- Modular Design: Quick assembly/disassembly for future expansion.

Project Results

- Output: 780 TPH (peak), meeting the client’s variable demand.

- Product Quality: 95% cubical aggregates, ideal for high-strength concrete.

- Downtime: <3% due to wear-resistant components (e.g., Mn18Cr2 jaw plates).

Client Feedback

“Liming’s team provided end-to-end support, from plant design to commissioning. The HST315 Cone Crusher and VSI6X sand maker exceeded our expectations in handling Yemen’s tough basalt. Their equipment’s durability and after-sales service are unmatched.”

— Project Manager, Yemen Customer

Custom Crushing Solutions For All

Mining & Aggregates Needs

while minimizing operational costs through smart, sustainable designs.

Key Equipment

VSI6X Sand Making Machine

PE Jaw Crusher

S5X Vibrating Screen