With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Projects

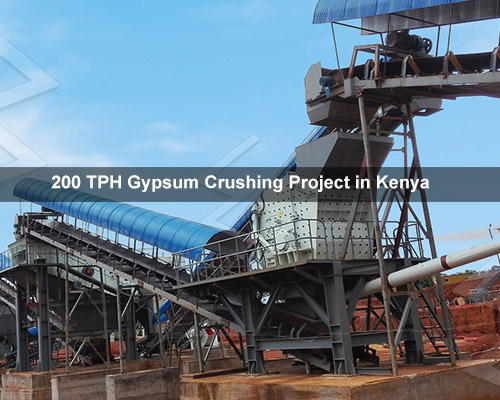

200 TPH Gypsum Crushing Project in Kenya

Client Profile:

A leading construction materials supplier in Kenya sought a reliable partner to establish a 200 TPH gypsum crushing plant. The client required durable, high-yield equipment to produce consistent, high-quality aggregates for local infrastructure projects.

Project Overview:

- Material: Gypsum

- Capacity: 200 tons per hour

- Locations: Kenya

- Application: Construction and industrial use

Challenges:

- High abrasiveness of gypsum demanded wear-resistant machinery.

- Strict output size requirements (0–5mm, 5–20mm).

- Limited on-site technical expertise necessitated user-friendly equipment.

Solution & Equipment Configuration:

Liming Heavy Industry designed a turnkey solution featuring our flagship crushers and screening systems:

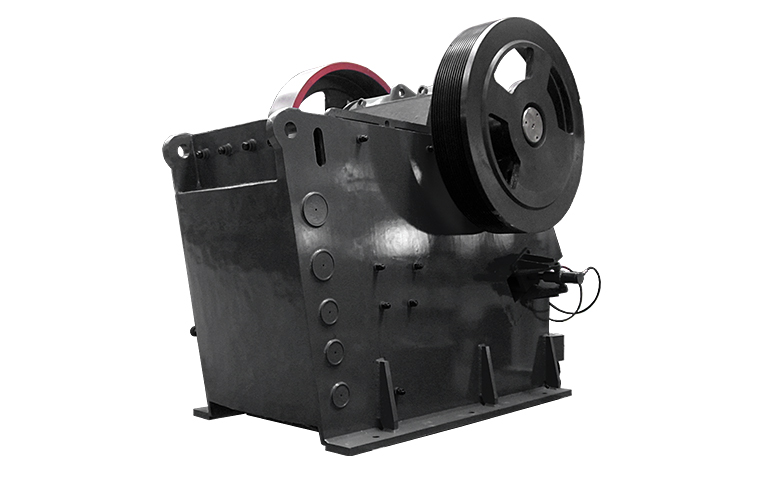

- Primary Crushing:PEW Series Jaw Crusher

- Role: Coarse crushing of raw gypsum (≤750mm) to ~150mm.

- Advantage: Deep crushing chamber and hydraulic adjustment for stable output.

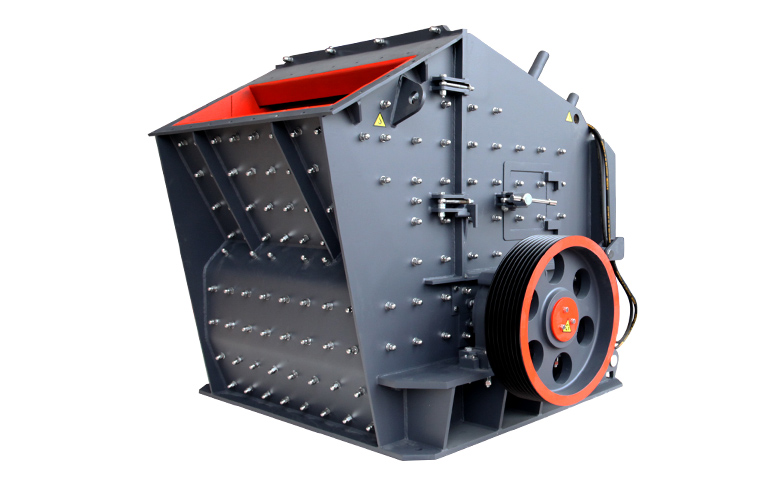

- Secondary Crushing:PFW Series Impact Crusher

- Role: Medium/fine crushing to ≤30mm.

- Advantage: Hydraulic system and heavy-duty rotor for high capacity and cubical output.

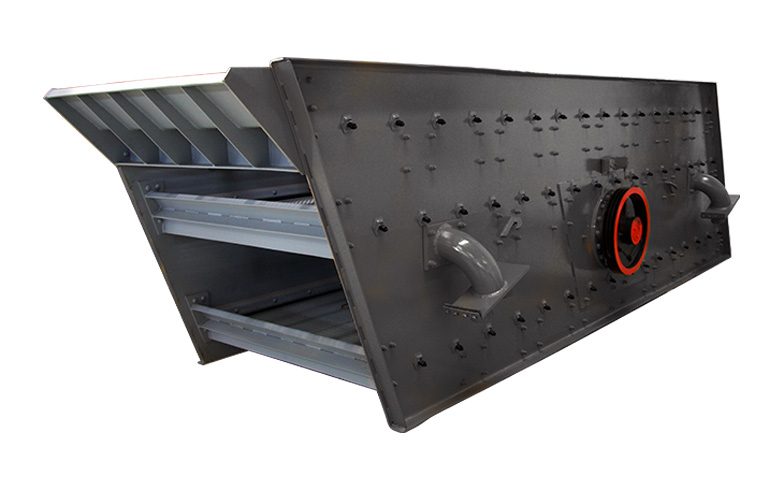

- Screening:YKN Series Vibrating Screen

- Role: Precise classification into 0–5mm and 5–20mm grades.

- Advantage: Polyurethane screens for longevity and high screening efficiency.

- Optional Add-On: VSI5X Sand Maker (for fines shaping if required).

Technical Highlights:

- Automated Control System: Reduced manual intervention.

- Dust Suppression: Integrated water spray system for environmental compliance.

- Modular Design: Quick assembly and minimal foundation requirements.

Results:

- Achieved steady 210 TPH output, exceeding the target by 5%.

- Final products met ISO 9001 standards for construction-grade aggregates.

- 25% lower maintenance costs due to wear-resistant alloys in crushers.

Client Feedback:

“Liming’s equipment outperformed our expectations. The PFW impact crusher handled gypsum effortlessly, and their team’s after-sales support ensured zero downtime.”

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

PFW Impact Crusher

Mining & Quarrying: Efficiently crushes ores (gold, iron, copper) and aggregates. Construction: Processes limestone, concrete, and demolition waste for road/base materials. Recycling:.

Learn More

YKN Vibrating Screen

Mining & Minerals: Ideal for grading coal, iron ore, copper, and gold ore. Aggregates & Sand: Efficiently screens crushed stone, gravel, and.

Learn More

PEW Jaw Crusher

Mining: Ideal for primary crushing of hard ores (gold, iron, copper) and abrasive rocks. Quarrying: Efficiently processes granite, basalt, and other aggregates.

Learn More

VSI5X Sand Making Machine

Mining & Quarrying – Crushes hard and abrasive materials (granite, basalt, limestone). Cement & Concrete Production – Enhances strength with cubical, fines-controlled.

Learn More