With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Projects

350 TPH Granite Crushing Plant in Nigeria

Customer Background

Our client is a leading construction and mining company in Nigeria specializing in granite quarrying and aggregate production. With increasing infrastructure demands, they needed a high-capacity, efficient, and durable granite crushing plant to meet the growing market needs.

Project Overview

- Location: Nigeria

- Material: Granite

- Required Output: 300-350 tons per hour

- Final Product: 0-5mm, 5-10mm, 10-20mm, and 20-40mm aggregates for construction

Challenges

- High Hardness of Granite – Requires robust and wear-resistant crushing machinery.

- High Production Demand – Needs a stable and large-capacity crushing plant.

- Strict Output Gradation – Requires precise control over particle sizes.

- Cost-Effective Operation – Must minimize downtime, maintenance, and power consumption.

Solution by Liming Heavy Industry

To meet these challenges, we designed a complete granite crushing and screening solution using our high-performance equipment:

1. Primary Crushing – PE1200×1500 Jaw Crusher

- Role: Coarse crushing of large granite blocks (up to 1000mm) into smaller rocks.

- Advantages:

- High crushing ratio and strong structure for granite processing.

- Large feed opening and deep crushing chamber for improved throughput.

- Energy-efficient operation reduces operational costs.

2. Secondary Crushing – HST315 Hydraulic Cone Crusher

- Role: Further crushing of coarse granite into medium-sized aggregates (10-40mm).

- Advantages:

- Advanced hydraulic system for stable output and optimal particle shape.

- Automatic overload protection to prevent damage from uncrushable materials.

- High wear resistance with manganese steel liners.

3. Sand Making – VSI6X1150 Impact Crusher

- Role: Produces high-quality 0-5mm sand for construction applications.

- Advantages:

- Deep rotor design maximizes sand yield and shapes product into cubic particles.

- Low energy consumption and high efficiency for sustainable operations.

- Reduced wear with advanced material flow design.

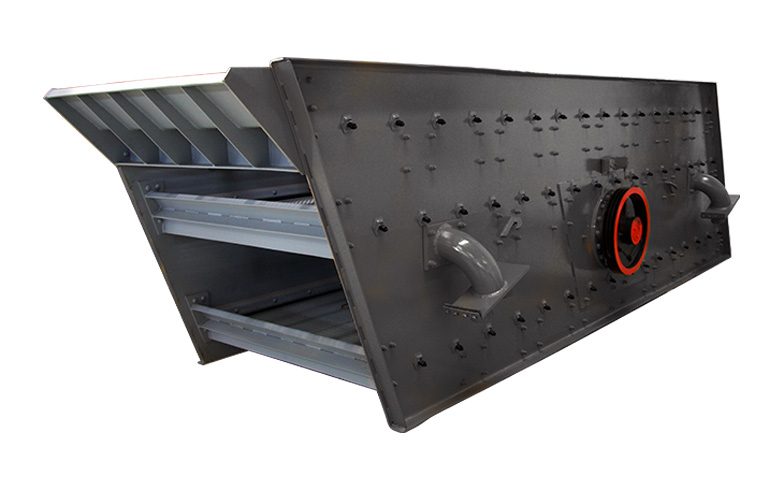

4. Screening – YKN2460 Vibrating Screen

- Role: Classifies crushed materials into precise size fractions.

- Advantages:

- High screening efficiency with customizable meshes.

- Large processing capacity for seamless integration into the production line.

- Durable construction with minimal maintenance requirements.

5. Supporting Equipment

- Belt conveyors (B1200, B1000) for smooth material transfer.

- Dust control system for environmental compliance.

Technical Highlights

- High Automation Control – PLC system ensures smooth operation with real-time monitoring.

- Energy-Efficient Design – Optimized equipment layout reduces power consumption.

- Durability & Reliability – Premium wear-resistant materials extend machine lifespan.

- Easy Maintenance – Modular design facilitates quick component replacement.

Project Results

- Production Capacity Achieved: 350 TPH (exceeding initial requirements).

- Final Product Quality: Well-graded 0-5mm sand + multiple aggregate sizes.

- Reduced Downtime: Reliable operation with minimal mechanical failures.

- Cost Savings: Lower energy and maintenance expenses compared to competitors.

Customer Feedback

“Liming Heavy Industry provided us with a top-notch crushing plant that perfectly handles our granite processing needs. The equipment is efficient, durable, and delivers consistent high-quality aggregates. Their technical support team has been exceptional in ensuring smooth operations.”

— Project Manager, Nigeria Client

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

HST Hydraulic Cone Crusher

The HST Hydraulic Cone Crusher is ideal for: Mining: Efficient crushing of ores (iron, copper, gold, etc.) Quarrying: Processing hard rocks (granite,.

Learn More

VSI6X Sand Making Machine

Construction: Produces high-grade sand for concrete, asphalt, and ready-mix plants. Mining: Processes iron ore, gold ore, and non-metallic minerals into fine aggregates..

Learn More

YKN Vibrating Screen

Mining & Minerals: Ideal for grading coal, iron ore, copper, and gold ore. Aggregates & Sand: Efficiently screens crushed stone, gravel, and.

Learn More

PE Jaw Crusher

Ideal for primary crushing of various materials: Mining/Ore Processing: Crushing gold, copper, iron ore, and manganese. Aggregates & Construction: Granite, basalt, limestone,.

Learn More