Projects

50-100 TPH Copper Ore Processing Project in Tanzania

Client Background

Our client is a well-established mining company in Tanzania specializing in copper ore extraction and processing. They were in need of an efficient and durable crushing solution to boost their production capacity while maintaining low operational costs.

Project Overview

The project required processing copper ore with a target capacity of 50-100 tons per hour (TPH). The client needed a crushing plant that could handle medium to high hardness copper ore while ensuring stable performance, minimal downtime, and energy efficiency.

Challenges

- Material Hardness – Copper ore is relatively hard, requiring robust crushing equipment.

- Production Demand – Achieving 50-100 TPH consistently while maintaining uniform output size.

- Durability & Maintenance – Reducing wear parts replacement frequency in abrasive conditions.

- Energy Efficiency – Optimizing power consumption to lower operational costs.

Solution: Optimized Crushing Plant by Liming Heavy Industry

After evaluating the project requirements, Liming Heavy Industry designed a turnkey crushing line tailored for copper ore processing, consisting of the following equipment:

1. Primary Crushing – PE Series Jaw Crusher (PE600×900)

- Role: Primary crushing of raw copper ore (≤500mm) into smaller pieces (≤150mm).

- Advantages: High crushing ratio, sturdy structure, and low energy consumption.

2. Secondary Crushing – HPT Multi-Cylinder Hydraulic Cone Crusher (HPT300)

- Role: Further reduces the copper ore into smaller sizes (≤30mm).

- Advantages:

- Hydraulic adjustment for precise output control.

- Higher productivity with lower wear rates.

- Advanced automation for optimized performance.

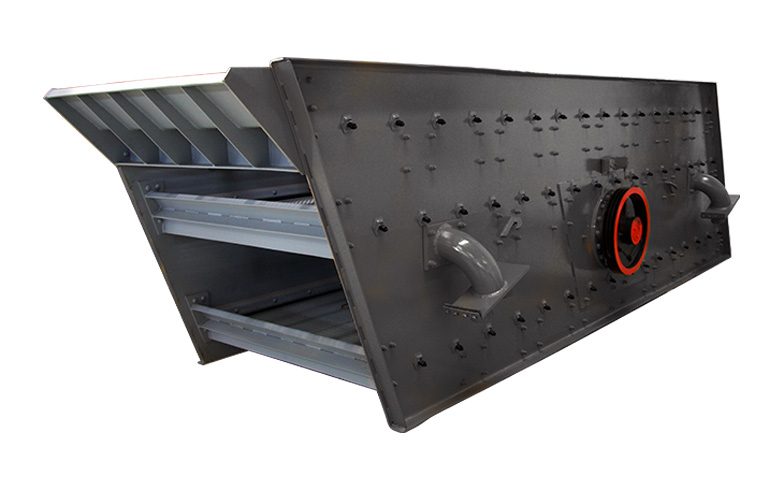

3. Screening – YK Series Vibrating Screen (YK1860)

- Role: Sorting crushed copper ore into desired sizes for further processing.

- Advantages:

- High screening efficiency with multi-layer configurations.

- Durable structure for long-term operation in harsh mining conditions.

Technical Highlights

- Automated Control System: Ensures smooth operation and real-time monitoring.

- Energy-Efficient Motors: Reduce power consumption without compromising production.

- Wear-Resistant Materials: Extend equipment lifespan in abrasive copper ore crushing.

Project Results

- Stable Output: Achieved consistent 50-100 TPH production capacity.

- Uniform Product Size: Met the client’s downstream processing requirements.

- Low Maintenance Costs: Reduced wear parts replacement frequency.

- High ROI: Energy-efficient operation lowered long-term expenses.

Client Feedback

“Liming Heavy Industry provided a reliable and efficient crushing plant for our copper ore processing. Their jaw crusher and cone crusher have performed exceptionally well, ensuring high productivity with minimal downtime. The support team was professional throughout the installation and after-sales service. We highly recommend their mining solutions.”

Custom Crushing Solutions For All

Mining & Aggregates Needs

while minimizing operational costs through smart, sustainable designs.

Key Equipment

YKN Vibrating Screen

HPT Hydraulic Cone Crusher