Projects

Iron Slag Processing Project in Algeria

Client Overview

Client Location: Algeria

Material: Iron Slag

Required Capacity: 100-1000 TPH

Our client in Algeria specializes in metal recycling and needed an efficient crushing solution to process iron slag into reusable materials. They required a durable, high-capacity system capable of handling varying feed sizes while maintaining high productivity.

Project Overview

The project involved designing and installing a complete iron slag crushing plant to achieve 100–1000 TPH output. The system needed to ensure low wear, easy maintenance, and energy-efficient operation for long-term cost savings.

Challenges

- High Hardness & Abrasiveness – Iron slag is tough and abrasive, demanding wear-resistant machines.

- Variable Feed Size – Large and irregular slag pieces required primary and secondary crushing.

- Dust & Noise Control – Environmental regulations required minimized dust and noise emissions.

- Scalability – The system needed to adapt to fluctuating production demands (100-1000 TPH).

Solution: Liming Heavy Industry’s Crushing Plant

To meet these challenges, we configured a customized crushing line with high-performance equipment:

1. Primary Crushing: PE Series Jaw Crusher

- Model: PE1200×1500

- Capacity: 400-800 TPH

- Role: Primary reduction of large iron slag chunks.

- Advantages: Heavy-duty structure, deep crushing chamber, high manganese steel jaw plates for extended service life.

2. Secondary Crushing: HST Hydraulic Cone Crusher

- Model: HST315

- Capacity: 500-1000 TPH

- Role: Fine crushing to produce uniform output (10-50mm).

- Advantages: Fully hydraulic adjustment, high crushing efficiency, and reduced downtime for maintenance.

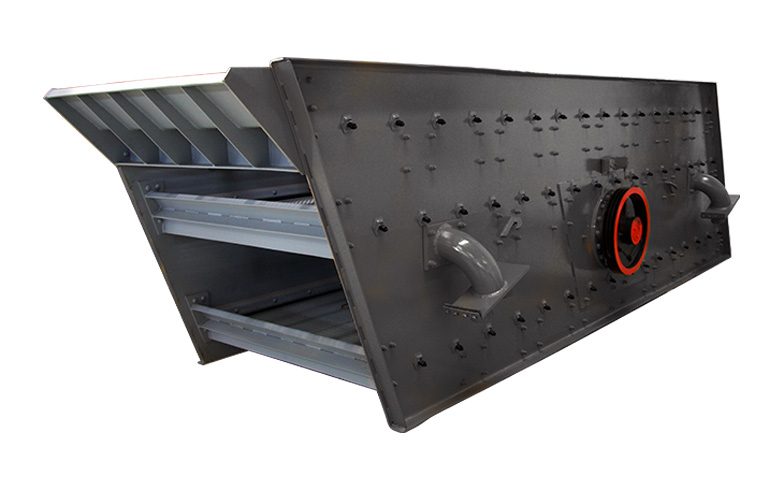

3. Screening: YK Series Vibrating Screen

- Model: YK3673

- Role: Precise grading of crushed slag into different sizes.

- Advantages: Multi-layer screening, high throughput, and durable screen mesh for consistent performance.

4. Dust Suppression System

- Equipment: Water spray system + bag filters

- Role: Reducing dust emissions for compliance with environmental standards.

Technical Highlights

- High Wear Resistance – Crusher liners and screens made of Mn steel for prolonged use

- Automated Hydraulic System – Ensures stable crushing performance with minimal manual intervention

- Energy Efficiency – Optimized motor and drive system reduce power consumption

- Scalable Output – Modular design allows expansion up to 1000 TPH.

Project Results

- Throughput Achieved: 100–1000 TPH (adjustable based on demand)

- Final Product Size: 0-5mm, 5-10mm, 10-30mm (meeting industrial standards)

- Wear Life Extended: Jaw plates lasted 3X longer than competitors’ models

- Dust Control Success: Dust emissions reduced by 90%, meeting Algerian environmental regulations.

Client Feedback

“Liming Heavy Industry’s crushing line exceeded our expectations. The PE1200×1500 jaw crusher and HST315 cone crusher handled our toughest iron slag efficiently, with minimal downtime. Their aftersales support has also been excellent.” — Project Manager, Algeria Client

Custom Crushing Solutions For All

Mining & Aggregates Needs

while minimizing operational costs through smart, sustainable designs.

Key Equipment

PE Jaw Crusher

HST Hydraulic Cone Crusher