With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Projects

Saudi Arabia 100 TPH Basalt Sand & Aggregate Plant

Project Background

The client sought a reliable solution to process hard basalt into high-quality sand and aggregates for local infrastructure development. Key requirements included:

- High yield (100TPH) with stable output.

- Low maintenance costs for abrasive basalt.

- Modular design for easy installation in remote locations.

Challenges

- Hard Material: Basalt’s high compressive strength (up to 300MPa) demands rugged equipment.

- Abrasion Wear: Conventional crushers suffer rapid wear when processing basalt.

- Dust Control: Strict environmental regulations in Saudi Arabia required low-dust operation.

Solution: Liming’s Customized Crushing Line

Liming Heavy Industry designed a 3-stage crushing and screening system:

- Primary Crushing: [C6X Jaw Crusher]

- Model: C6X145

- Role: Coarse basalt crushing (≤750mm feed size).

- Advantages: Robust frame, optimized cavity, and wedge adjustment for reduced downtime.

- Secondary Crushing: [HST Single Cylinder Cone Crusher]

- Model: HST250

- Role: Intermediate crushing to 40mm.

- Advantages: Hydraulic control for precise output, laminated crushing principle for lower wear.

- Tertiary Sand Making: [VSI6X Sand Maker]

- Model: VSI6X1263

- Role: Producing 0-5mm high-quality sand.

- Advantages: Rock-on-rock crushing, low noise, and ≤3% needle-like content.

- Auxiliary Equipment:

- Vibrating Feeder (ZSW490×130)

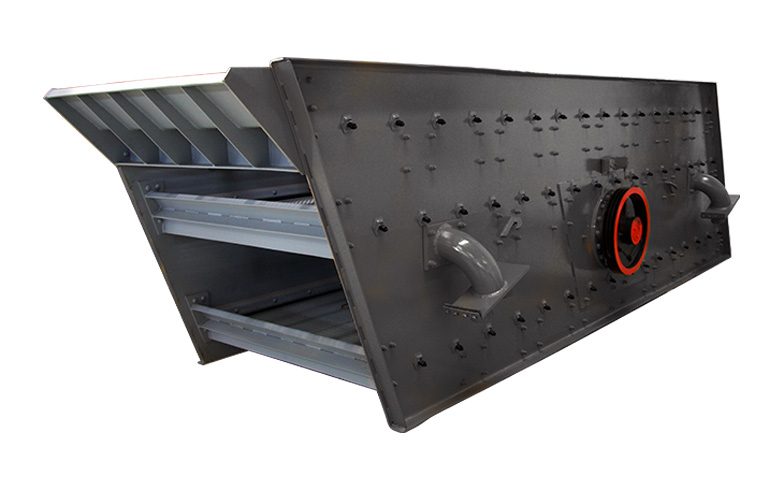

- Circular Vibrating Screen (3YK3072) for grading.

- Dust Suppression System (Meet Saudi EPA standards).

Technical Highlights

- Smart Control: PLC automation for real-time monitoring.

- Energy Efficiency: 20% lower power consumption vs. traditional lines.

- Modularity: Pre-assembled modules reduced on-site installation time by 30%.

Results

- Output: Steady 105-110TPH (exceeding target).

- Product Quality: Cube-shaped aggregates (≤15% flakiness) and ISO-standard sand.

- Maintenance: Wear parts lifetime extended by 40% due to Liming’s special alloy liners.

Client Feedback

“Liming’s team provided end-to-end support—from design to commissioning. The VSI6X sand maker’s performance in Saudi’s dusty environment impressed us. We plan to expand with another line next year.”

— Project Manager, Saudi Client

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

HST Hydraulic Cone Crusher

The HST Hydraulic Cone Crusher is ideal for: Mining: Efficient crushing of ores (iron, copper, gold, etc.) Quarrying: Processing hard rocks (granite,.

Learn More

VSI6X Sand Making Machine

Construction: Produces high-grade sand for concrete, asphalt, and ready-mix plants. Mining: Processes iron ore, gold ore, and non-metallic minerals into fine aggregates..

Learn More

YKN Vibrating Screen

Mining & Minerals: Ideal for grading coal, iron ore, copper, and gold ore. Aggregates & Sand: Efficiently screens crushed stone, gravel, and.

Learn More

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More