With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Projects

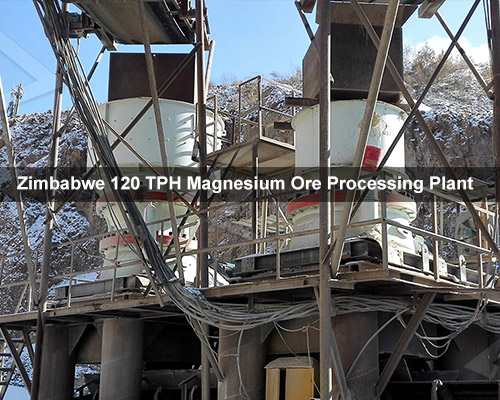

Zimbabwe 120 TPH Magnesium Ore Processing Plant

Client Profile

A mining company in Zimbabwe sought a reliable solution to process 120 TPH of magnesium ore into high-quality aggregates for industrial applications. The client needed durable, high-efficiency equipment to handle abrasive ore while minimizing downtime.

Project Overview

- Location: Zimbabwe

- Material: Magnesium ore (Mohs hardness: ~4-5)

- Capacity: 120 tons per hour

- Final Output: 0-30mm graded aggregates

Challenges

- High abrasiveness of magnesium ore required wear-resistant equipment.

- Strict output size (0-30mm) demanded precise crushing and screening.

- Local infrastructure limitations necessitated robust, low-maintenance machines.

Solution: Customized Liming Crushing & Screening Line

1. Primary Crushing: PE750×1060 Jaw Crusher

- Role: Coarse crushing of raw magnesium ore (≤500mm → 150mm).

- Advantages: High crushing ratio, durable manganese steel plates, low energy consumption.

2. Secondary Crushing: HST250 Single-Cylinder Hydraulic Cone Crusher

- Role: Further reduction (150mm → 30mm).

- Advantages: Hydraulic adjustment for precise output, laminated crushing principle for cubic-shaped aggregates.

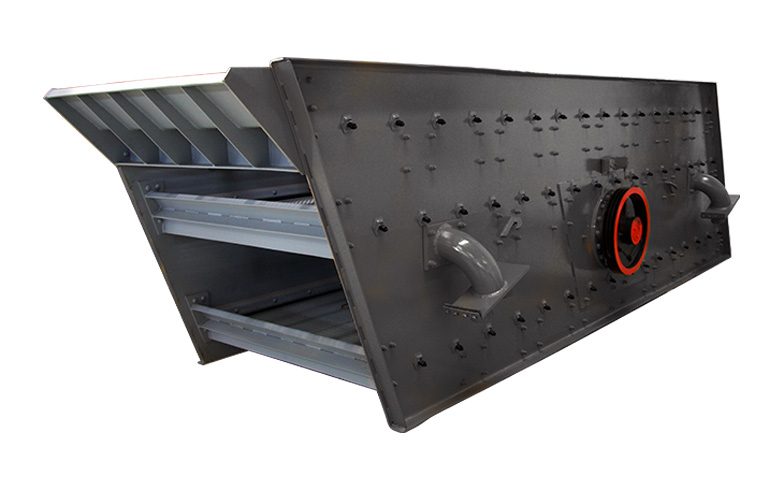

3. Screening: 3YZS2460 Vibrating Screen

- Role: Grading crushed ore into 0-10mm, 10-20mm, and 20-30mm sizes.

- Advantages: Multi-layer screening, high efficiency, and noise reduction design.

Supporting Equipment:

- Belt Conveyors (B1000×20m): Seamless material transfer between stages.

- Electric Control System: Automated operation for safety and efficiency.

Technical Highlights

- Wear-resistant Materials: Critical parts (e.g., jaw plates, mantle) use Mn18Cr2 alloy for extended lifespan.

- Energy Efficiency: HST Cone Crusher reduces power consumption by 15% vs. traditional crushers.

- Modular Design: Quick installation and minimal foundation requirements for remote sites.

Project Results

- Achieved Capacity: Steady 120 TPH output, meeting client’s production targets.

- Product Quality: 95% of output met 0-30mm specs with low flakiness.

- Operational Efficiency: Over 85% uptime thanks to Liming’s low-maintenance design.

Client Feedback

“Liming’s team provided end-to-end support, from equipment selection to commissioning. Their PE Jaw Crusher and HST Cone Crusher handled our tough magnesium ore without breakdowns. The plant now runs smoothly, and the after-sales service is excellent.”

— Mining Director, Zimbabwe Client

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

HST Hydraulic Cone Crusher

The HST Hydraulic Cone Crusher is ideal for: Mining: Efficient crushing of ores (iron, copper, gold, etc.) Quarrying: Processing hard rocks (granite,.

Learn More

YKN Vibrating Screen

Mining & Minerals: Ideal for grading coal, iron ore, copper, and gold ore. Aggregates & Sand: Efficiently screens crushed stone, gravel, and.

Learn More

PE Jaw Crusher

Ideal for primary crushing of various materials: Mining/Ore Processing: Crushing gold, copper, iron ore, and manganese. Aggregates & Construction: Granite, basalt, limestone,.

Learn More