Applications

Ballast Crusher

Ballast Processing with Liming Heavy Industry’s Advanced Crushers

Ballast forms the essential foundation for railway tracks, providing drainage, stability, and load distribution. At Liming Heavy Industry, we specialize in manufacturing premium ballast crushers that produce precisely graded aggregate for rail infrastructure projects worldwide.

Why Ballast Crushing Matters

Railway ballast must meet strict specifications regarding:

- Size (typically 25-50mm)

- Angularity (for interlocking stability)

- Durability (to withstand heavy loads and weather)

- Cleanliness (low fines content)

Our specialized ballast crushing equipment ensures all these quality requirements are met efficiently.

The Ballast Crushing Process

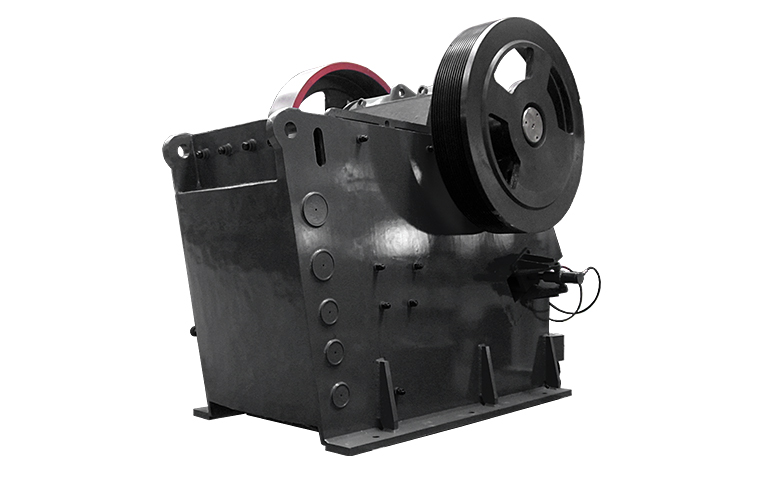

1. Primary Crushing with Jaw Crushers

Liming’s PE Series Jaw Crushers (like PE600×900) perform the initial size reduction of large ballast rocks (up to 1m) down to about 200mm. These robust crushers feature:

- Deep crushing chamber for high capacity

- Optimized nip angle for better particle shape

- Heavy-duty construction for continuous operation

2. Secondary Crushing with Impact Crushers

Our PF/PFW Series Impact Crushers further reduce material to the ideal 25-50mm ballast size while creating the angular particles crucial for track stability. Benefits include:

- High cubicle product shape

- Adjustable output size

- Hydraulic opening system for easy maintenance

3. Screening Process

Proper sized ballast requires precise screening. Liming’s YKN/YZS Vibrating Screens efficiently separate:

- Oversize material (returned for recrushing)

- Correct-sized ballast (25-50mm)

- Undersize fines (removed to ensure proper drainage)

4. Optional Tertiary Crushing with Cone Crushers

For projects requiring particularly uniform ballast, our HPT/HST Series Cone Crushers provide:

- Consistent particle size distribution

- Low wear costs

- Automated control systems

Why Choose Liming Ballast Crushers?

- Proven Performance: Our crushers are operational in railway projects across Asia, Africa and South America

- Durability: Heavy-duty construction withstands tough ballast stone like basalt and granite

- Energy Efficiency: Advanced designs reduce power consumption per ton of ballast produced

- Custom Solutions: We offer complete ballast processing plants (Jaw+Impact+Screening)

- Service Support: Global network ensures prompt maintenance and spare parts supply

Technical Highlights

- Production capacity: 50-800tph ballast crushing plants available

- End product: 25-50mm with <3% fines content

- Power options: Electric or diesel-electric configurations

For railway contractors and ballast producers, Liming Heavy Industry provides end-to-end solutions from single machines to complete turnkey plants. Our ballast crushers deliver the quality aggregate that keeps rail networks stable and safe.

Custom Crushing Solutions For All

Mining & Aggregates Needs

while minimizing operational costs through smart, sustainable designs.

Key Equipment

PEW Jaw Crusher

PF Impact Crusher

CI5X Impact Crusher

C6X Jaw Crusher

HPT Hydraulic Cone Crusher