In the competitive mining and construction aggregate industry, achieving a balance between high output and low operational costs is the ultimate goal. For many quarry owners, a 300TPH stone crushing plant layout & design represents the “sweet spot”—large enough to handle major infrastructure contracts, yet efficient enough to maintain manageable overhead. However, a poorly designed layout can lead to bottlenecking, excessive wear, and high energy consumption.

Liming Heavy Industry specializes in providing turnkey solutions that optimize material flow and equipment longevity. Whether you are processing hard granite, abrasive basalt, or limestone, our engineered designs ensure your 300TPH plant delivers consistent results from day one.

Core Principles of an Effective 300TPH Stone Crushing Plant Layout

A successful design isn’t just about placing machines in a row; it’s about understanding the physics of material movement. When we approach a 300TPH stone crushing plant layout & design, we focus on three primary factors:

- Topography Utilization: Using natural gravity to move materials between crushers to reduce conveyor power costs.

- Scalability: Ensuring there is enough space for maintenance and potential future upgrades.

- Material Characteristics: Adjusting the crushing ratio based on the hardness and moisture content of the raw stone.

Recommended Equipment Configuration for 300TPH Capacity

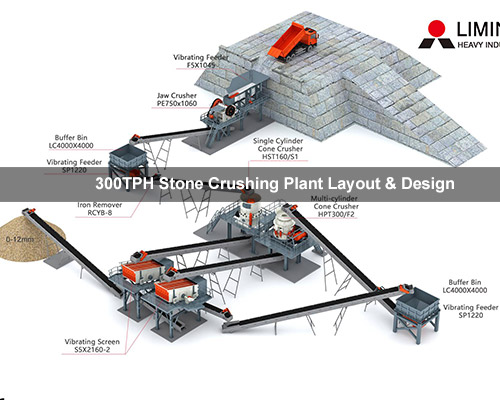

To achieve a stable output of 300 tons per hour, Liming Heavy Industry typically recommends a multi-stage crushing process. Below is a standard configuration for hard rock (e.g., Granite or Blue Stone):

| Stage | Equipment Recommendation | Function |

|---|---|---|

| Primary Crushing | PE900×1200 Jaw Crusher | Initial reduction of large feed sizes (up to 750mm). |

| Secondary Crushing | HST250 Single Cylinder Cone Crusher | Fine crushing to achieve uniform medium-sized particles. |

| Tertiary Crushing (Optional) | HPT Series Multi-cylinder Cone Crusher | Final shaping for high-quality aggregate requirements. |

| Screening | 2YZS2460 Vibrating Screen | Separating finished products into 0-5mm, 5-10mm, 10-20mm, etc. |

Step-by-Step Design Flowchart

1. Feeding and Primary Crushing

The raw material is fed via a GZD1300×4900 vibrating feeder into the Jaw Crusher. The feeder removes soil and fines before crushing, which reduces wear on the primary machine and increases overall efficiency.

2. Intermediate Stockpiling

In a professional 300TPH stone crushing plant layout & design, we often include a buffer silo or stockpile between the primary and secondary stages. This ensures that even if the primary crusher stops momentarily, the rest of the plant continues to operate.

3. Secondary & Tertiary Crushing

For hard stone, cone crushers are the preferred choice due to their high crushing force and low operating costs compared to impact crushers. Liming’s HST and HPT series provide automated hydraulic adjustments to control output size precisely.

Advantages of Liming’s 300TPH Solution

- High Automation: Equipped with PLC control systems to monitor temperature, oil pressure, and load in real-time.

- Optimized Grain Shape: Our crushing cavities are designed to produce cubic aggregates that meet international construction standards for high-strength concrete.

- Dust Control: Integrated water spray systems and dust collectors ensure the plant meets modern environmental regulations in regions like Southeast Asia and Africa.

ROI Analysis: Why Invest in a 300TPH Design?

While the initial investment for a 300TPH plant is higher than smaller mobile units, the ROI is significantly faster for medium-to-large-scale contractors. By optimizing the 300TPH stone crushing plant layout & design, owners can reduce energy consumption by up to 15% and extend the life of wear parts by 20%, leading to a lower “cost per ton.”

FAQ: Frequently Asked Questions

How much space is required for a 300TPH stone crushing plant?

Generally, a stationary 300TPH plant requires approximately 1,500 to 3,000 square meters, depending on the number of finished product piles and the complexity of the screening section.

Can this layout handle wet or sticky materials?

Yes. For sticky materials, we modify the layout by adding a scalping screen before the primary jaw crusher and using specialized anti-clogging screen meshes.

What is the typical lead time for a custom plant design?

At Liming Heavy Industry, we provide the initial layout and design within 3-5 business days after receiving your site specifications and rock analysis report.

A 300TPH stone crushing plant layout & design is the backbone of any serious aggregate production business. By choosing the right combination of jaw and cone crushers and optimizing the flow through expert engineering, you ensure long-term profitability and operational stability.

Contact Liming Heavy Industry today for a customized plan and price list tailored to your specific project needs. Our engineers are ready to help you build a high-efficiency production line.