With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Applications

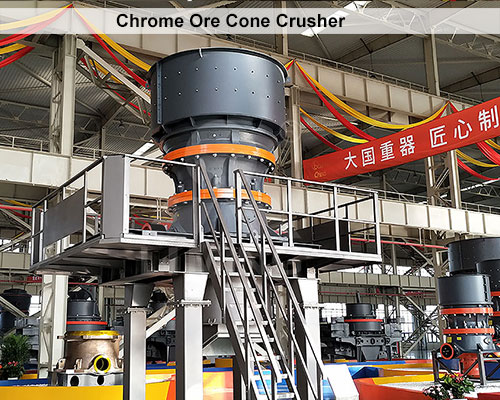

Chrome Ore Crusher

The Critical Role of Crushing in Chrome Ore Beneficiation

Chromite (FeCr₂O₄) requires precise size reduction to liberate chrome spinels while minimizing fines generation. As a global leader in mining equipment, Liming Heavy Industry engineers Chrome Ore Crushers optimized for ultra-hard, abrasive chromite ores with unconfined compressive strength (UCS) up to 300 MPa.

Stage 1: Primary Crushing – ROM Ore Reduction

- Challenge: Breaking massive chromite lumps (≤800mm) with high toughness

- Solution: Heavy-duty Jaw Crushers with reinforced structures

Liming Equipment:- C6X Series Jaw Crusher (e.g. C6X145)

- Eccentric forged shaft for 560mm feed size

- 35% longer jaw plate life with MX manganese steel

- PE Series Jaw Crusher (e.g. PE1200×1500)

- ≤220mm output for South African UG2 ore

- C6X Series Jaw Crusher (e.g. C6X145)

Stage 2: Secondary Crushing – Chromite Liberation

- Challenge: Achieving 25-50mm optimal feed size for gravity separation

- Solution:Multi-cylinder Hydraulic Cone Crushers

Liming Equipment:- HPT Series Cone Crusher (e.g. HPT400)

- Laminated crushing preserves chromite crystal integrity

- Automatic tramp iron release protects mantle

- HST Series Cone Crusher (e.g. HST315)

- ≤30mm product for friable Indian chromite

- HPT Series Cone Crusher (e.g. HPT400)

Stage 3: Tertiary Crushing (Optional) – Fines Control

- Challenge: Minimizing -1mm slimes for improved spiral recovery

- Solution:Fine Cone Crushers with precise CSS control

Liming Equipment:- HPT500 Fine Cavity Cone Crusher

- 8-15mm output for pelletized chromite

- Hydraulic over-pressure protection

- HPT500 Fine Cavity Cone Crusher

Integrated Auxiliary Systems

- S5X Vibrating Screen (e.g. S5X2460-3)

- Polyurethane flip-flow screens for sticky ore

- B6X Belt Conveyor

- Impact beds prevent chromite lump degradation

Technical Advantages of Liming Chrome Crushers

| Feature | Chromite Application Benefit |

|---|---|

| Patented MX Jaw Plates | 2.8x lifespan vs standard manganese |

| Intelligent Hydraulic System | Real-time CSS adjustment (±2mm) |

| Dust-Proof Bearing | Zero contamination in high-SiO₂ ores |

| Modular Wear Parts | 4hr mantle change for HPT series |

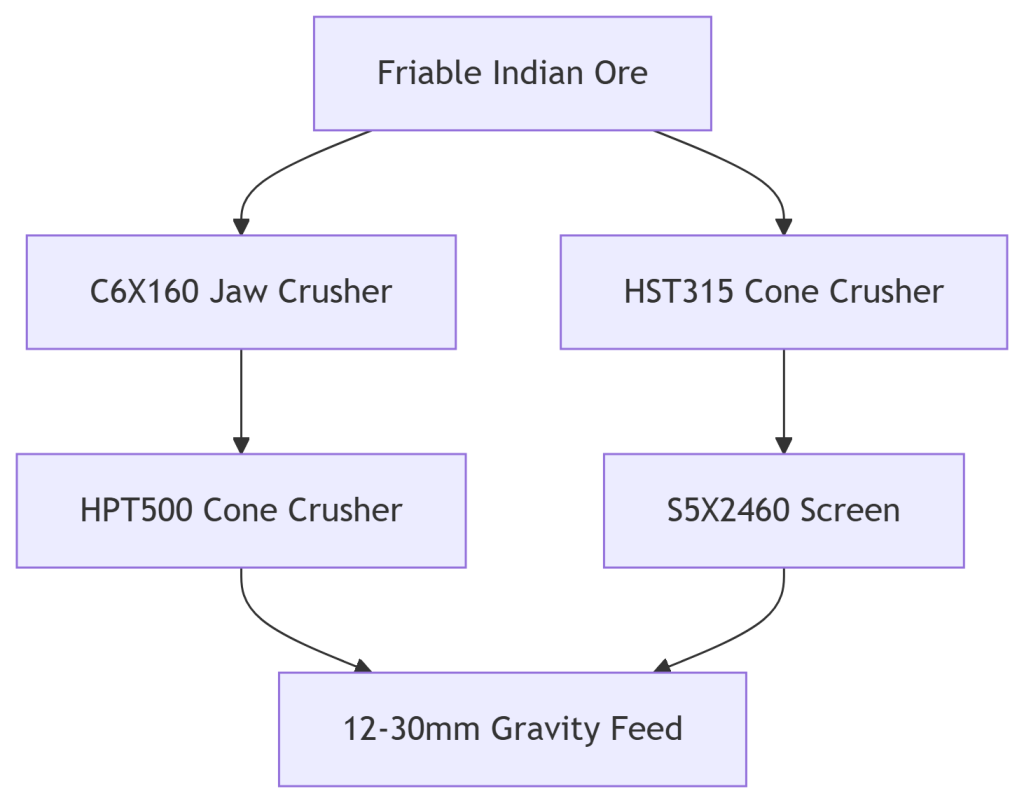

Configuration for Major Chrome Types

Performance Data (Turkey 400TPH Plant):

- Ore Type: Podiform chromite (UCS 250 MPa)

- Final Product: 85% 10-30mm (ideal for jig separation)

- Crusher Wear Rate: 0.8g/ton for HPT500 mantles

Why Choose Liming for Chrome Processing?

“Over-crushing chromite generates 15-25% slimes – precise size control is critical for +46% Cr₂O₃ concentrate.”

– Liming Mineral Processing Team

Tailored Solutions for:

- Lumpy Ores: C6X + HPT circuit with 8:1 reduction

- Fine Disseminated Ores: HST single-stage crushing

- Mobile Requirements: K3-2385 Plant with integrated screen

Request Chrome Ore Test Report:

→ Submit ore samples for free crushing analysis using Liming C6X/HPT crushers

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More

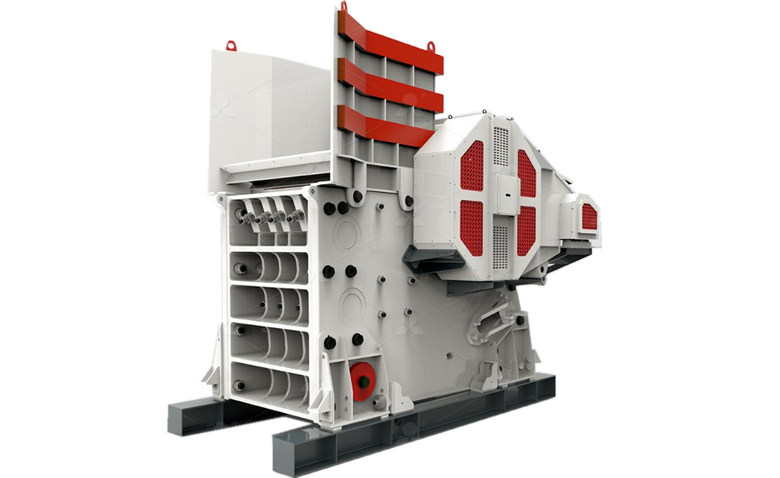

C5X Jaw Crusher

Mining & Ore Processing Ideal for primary crushing of iron ore, gold ore, copper ore, and other metallic/non-metallic minerals. Handles tough materials.

Learn More

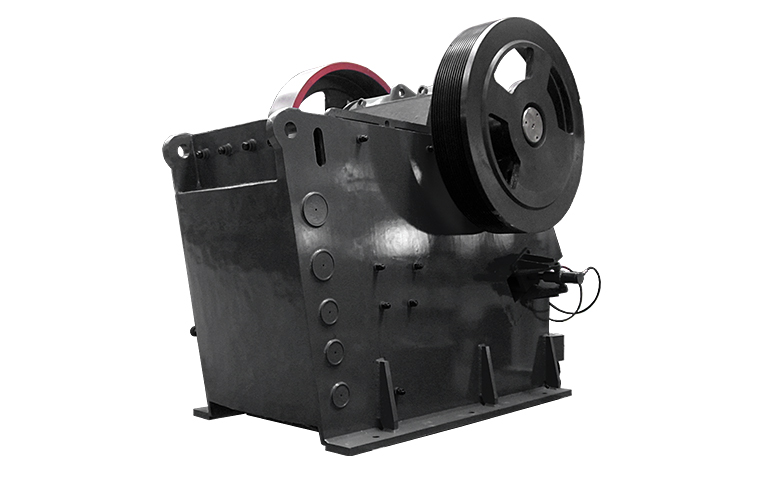

PE Jaw Crusher

Ideal for primary crushing of various materials: Mining/Ore Processing: Crushing gold, copper, iron ore, and manganese. Aggregates & Construction: Granite, basalt, limestone,.

Learn More

VSI6X Sand Making Machine

Construction: Produces high-grade sand for concrete, asphalt, and ready-mix plants. Mining: Processes iron ore, gold ore, and non-metallic minerals into fine aggregates..

Learn More

PEW Jaw Crusher

Mining: Ideal for primary crushing of hard ores (gold, iron, copper) and abrasive rocks. Quarrying: Efficiently processes granite, basalt, and other aggregates.

Learn More

HST Hydraulic Cone Crusher

The HST Hydraulic Cone Crusher is ideal for: Mining: Efficient crushing of ores (iron, copper, gold, etc.) Quarrying: Processing hard rocks (granite,.

Learn More