Applications

Copper Ore Crusher

Copper, a vital metal powering modern infrastructure and technology, begins its journey deep within the earth. Extracting and processing copper ore efficiently is crucial for meeting global demand. At Liming Heavy Industry, a leading manufacturer of stone crushing, mining crushing, mineral processing, and screening equipment, we provide robust and reliable crushing solutions specifically designed for the demanding nature of copper ore processing.

The Copper Ore Journey: Mining to Crushing

- Mining: Copper ore is typically extracted from open-pit or underground mines. The ore extracted varies significantly in size, composition (often containing sulfide or oxide minerals alongside gangue like silica), and hardness.

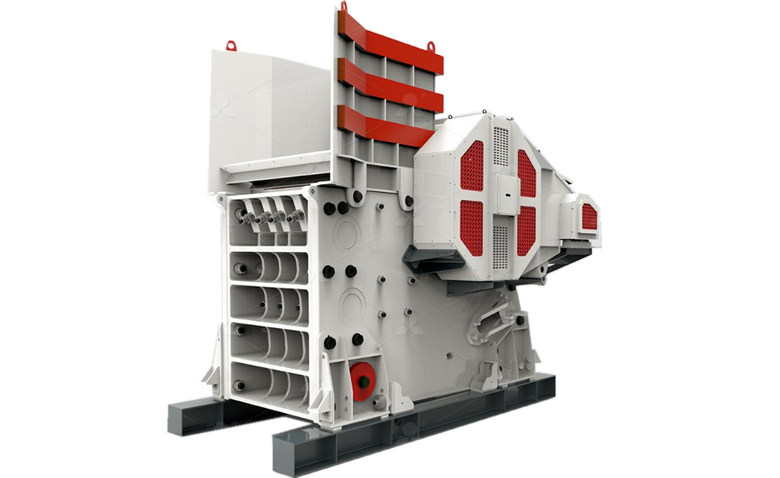

- Primary Crushing: The first critical step in liberating the valuable copper minerals is primary crushing. Large run-of-mine (ROM) ore, often exceeding 1 meter in size, needs to be reduced to manageable dimensions for further processing. This stage requires exceptionally strong and durable equipment capable of handling high throughput and potentially abrasive material.

- The Liming Solution: Our heavy-duty Jaw Crushers are the workhorses of primary copper ore crushing. Renowned for their deep crushing chambers, robust construction, and high reduction ratios, they efficiently break down large lumps into smaller fragments (typically 150-250mm).

- Featured Liming Primary Crushers for Copper Ore:

- PE Series Jaw Crusher: A classic, reliable choice known for its simplicity and strength. (e.g., PE600×900, PE750×1060, PE900×1200)

- C Series Jaw Crusher: Offering advanced features like modular design, optimized kinematics, and high capacity for demanding primary applications. (e.g., C6X Series like C6X100, C6X125, C6X145)

- Secondary Crushing: The output from the primary crusher needs further size reduction. Secondary crushing aims to produce material suitable for feeding grinding mills or tertiary crushers, typically reducing ore to sizes between 20-50mm. Copper ore often requires consistent size and shape for optimal downstream grinding efficiency.

- The Liming Solution: Cone Crushers excel in secondary crushing for copper ore. They provide precise control over the final product size and shape, producing a more cubical output essential for efficient grinding. Their inter-particle crushing action is highly effective for medium-hard to hard copper ores.

- Featured Liming Secondary Crushers for Copper Ore:

- HPT Multi-cylinder Hydraulic Cone Crusher: Engineered for high performance, efficiency, and product shape. Its hydraulic system allows easy adjustment and overload protection. (e.g., HPT200, HPT300, HPT400)

- HST Single Cylinder Hydraulic Cone Crusher: Combines simplicity with advanced technology, offering excellent productivity and fine crushing capabilities. (e.g., HST100, HST160, HST250)

- *(For specific applications or softer ores, an Impact Crusher like the CI5X Series might be suitable for secondary/tertiary duties)*

- Tertiary Crushing (Optional): In some circuits, especially where very fine feed for grinding is desired or for producing specific aggregate sizes, a tertiary crushing stage might be employed using finer cone crushers or high-pressure grinding rolls (HPGR).

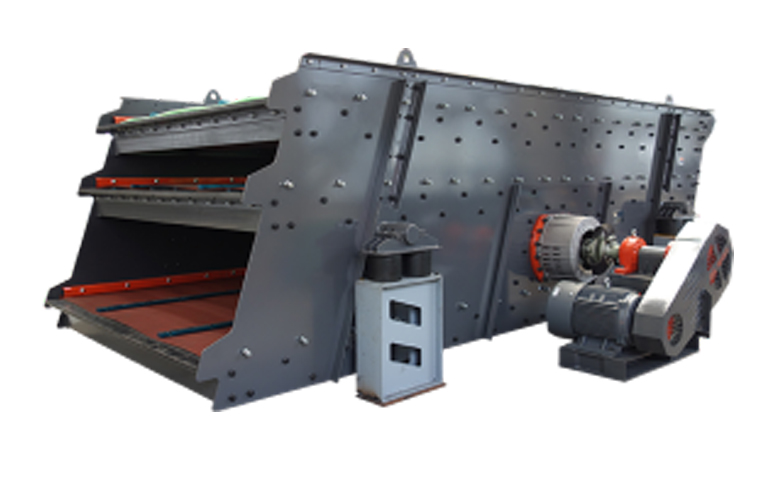

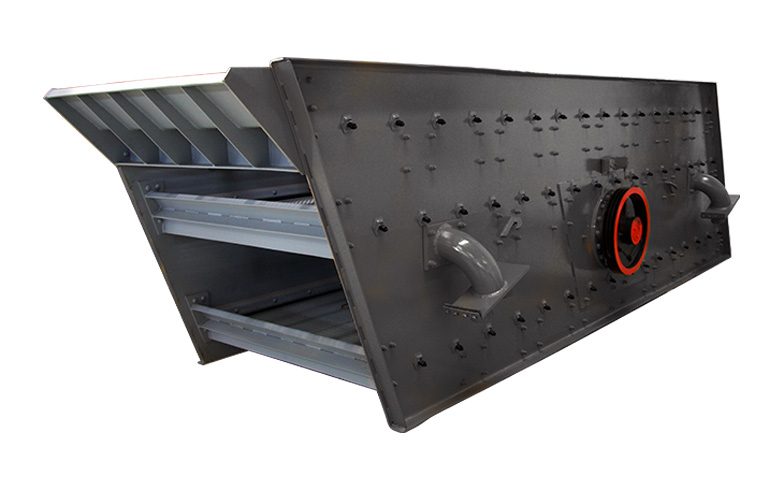

- Screening: Throughout the crushing stages, Vibrating Screens (like Liming’s S5X or Y Series) are essential for separating the crushed material into specific size fractions. Oversize material is recirculated back to the crusher, while correctly sized material proceeds to grinding or further processing.

Why Choose Liming Heavy Industry Copper Ore Crushers?

- Robustness & Durability: Built to withstand the abrasiveness and impact of tough copper ores, ensuring long service life and reduced downtime.

- High Efficiency & Capacity: Engineered designs maximize throughput and minimize energy consumption per ton of ore crushed.

- Precise Size Control: Advanced crushing chambers and hydraulic systems (in cone crushers) deliver consistent, well-graded product essential for downstream processes.

- Advanced Technology: Incorporating modern features like hydraulic adjustment, automated control systems, and optimized wear parts for lower operating costs.

- Comprehensive Solutions: Liming provides not just individual crushers, but complete crushing and screening plants tailored to your specific copper ore characteristics and production goals. We also offer grinding mills (like the MTW/MTM series) and other mineral processing equipment.

- Global Support: Backed by extensive experience and a global service network for installation, maintenance, and spare parts.

Optimizing Your Copper Ore Crushing Circuit

Selecting the right crusher and designing an efficient flow sheet is critical. Factors include ore hardness (e.g., Bond Work Index), moisture content, feed size, required product size, and overall plant capacity. Liming Heavy Industry’s engineering team can work with you to analyze your ore and recommend the optimal crushing solution using our proven Jaw Crushers (PE, C Series), Cone Crushers (HPT, HST Series), and supporting equipment.

Partner with Liming Heavy Industry for Your Copper Ore Crushing Needs

As a trusted manufacturer of crushers for mining and aggregates, Liming Heavy Industry is committed to providing high-performance, reliable crushing equipment that maximizes your copper processing efficiency and profitability. From primary jaw crushing to precision secondary cone crushing, we have the technology and expertise to support your operation.

Custom Crushing Solutions For All

Mining & Aggregates Needs

while minimizing operational costs through smart, sustainable designs.

Key Equipment

S5X Vibrating Screen

PE Jaw Crusher

YKN Vibrating Screen

C6X Jaw Crusher

HPT Hydraulic Cone Crusher