With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Applications

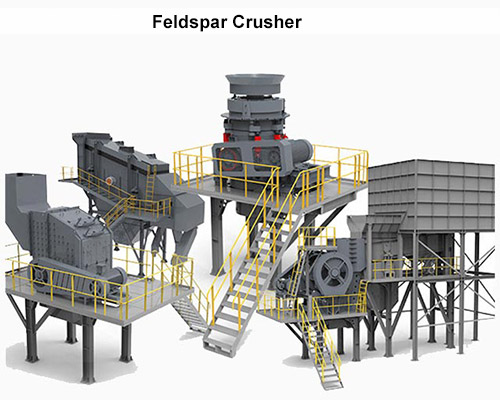

Feldspar Crusher

Introduction

Feldspar is a crucial raw material in ceramics, glass, and construction industries. Its extraction and processing require specialized crushing equipment to achieve the desired particle size. Liming Heavy Industry offers durable and high-performance feldspar crushers, ensuring efficient processing for mining and industrial applications.

Feldspar Mining Process

- Exploration & Extraction

- Feldspar deposits are drilled, blasted, and excavated.

- Raw ore is transported to processing plants for crushing and refinement.

- Primary Crushing (Coarse Crushing)

- Equipment Used: C6X Jaw Crusher / PE Jaw Crusher

- Large feldspar blocks are reduced to smaller pieces (typically 100–200 mm).

- Secondary Crushing (Intermediate Crushing)

- Equipment Used: CI5X Impact Crusher / HPT Hydraulic Cone Crusher

- Further reduces feldspar into finer particles (10–50 mm).

- Tertiary Crushing (Fine Grinding – Optional for Powder Production)

- Equipment Used: HST Cone Crusher (for ultra-fine particles).

- Screening & Washing

- Vibrating screens (S5X Series) separate crushed feldspar by size.

- Washing removes impurities.

Why Choose Liming Heavy Industry’s Feldspar Crushers?

- High Crushing Efficiency: Optimized cavity designs for superior feldspar reduction.

- Low Wear & Long Lifespan: Reinforced wear-resistant materials for abrasive ores.

- Energy-Saving & Eco-Friendly: Hydraulic adjustment systems reduce power consumption.

Application of Crushed Feldspar

- Ceramics & Glass Manufacturing (requires finely ground feldspar).

- Construction Materials (e.g., floor tiles, sanitaryware).

- Abrasive & Filler Industries.

For reliable feldspar crushing solutions, Liming Heavy Industry’s Feldspar Crushers (such as the C6X Jaw Crusher, CI5X Impact Crusher, and HPT Cone Crusher) deliver unmatched performance in mining and mineral processing.

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

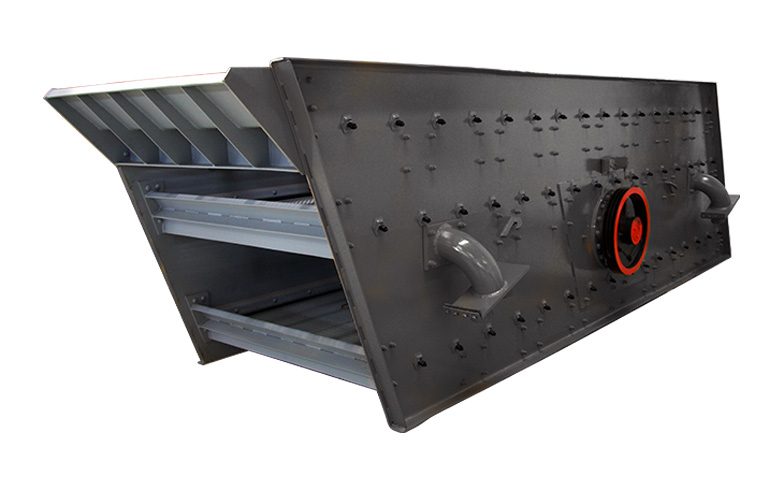

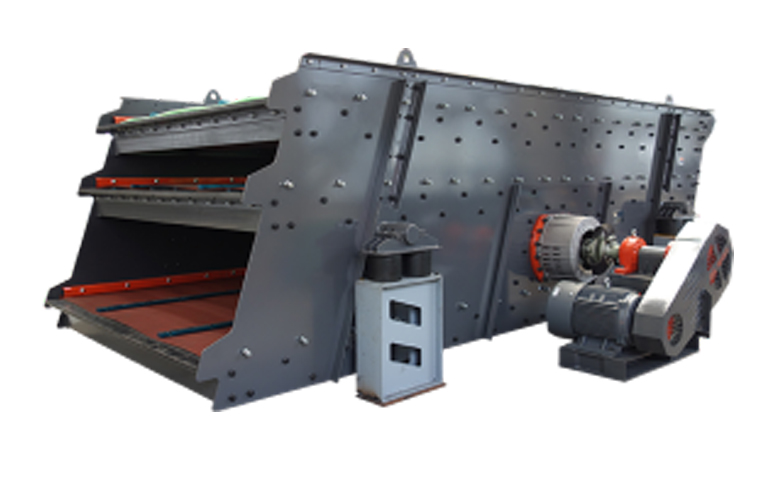

YKN Vibrating Screen

Mining & Minerals: Ideal for grading coal, iron ore, copper, and gold ore. Aggregates & Sand: Efficiently screens crushed stone, gravel, and.

Learn More

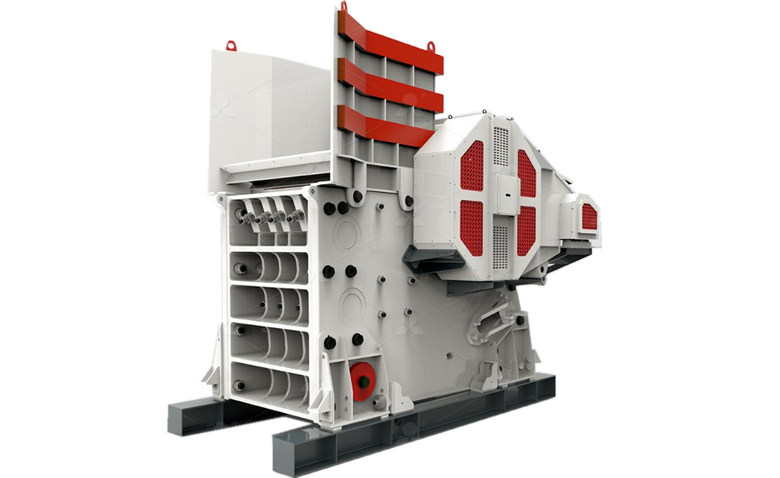

C5X Jaw Crusher

Mining & Ore Processing Ideal for primary crushing of iron ore, gold ore, copper ore, and other metallic/non-metallic minerals. Handles tough materials.

Learn More

PE Jaw Crusher

Ideal for primary crushing of various materials: Mining/Ore Processing: Crushing gold, copper, iron ore, and manganese. Aggregates & Construction: Granite, basalt, limestone,.

Learn More

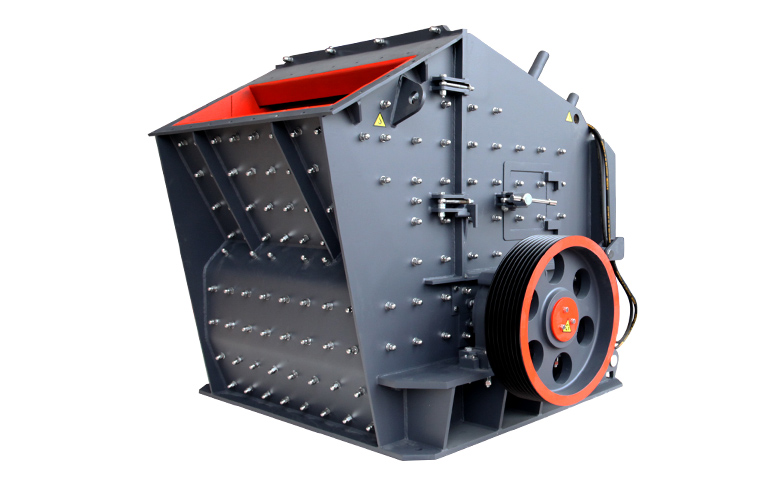

PFW Impact Crusher

Mining & Quarrying: Efficiently crushes ores (gold, iron, copper) and aggregates. Construction: Processes limestone, concrete, and demolition waste for road/base materials. Recycling:.

Learn More

S5X Vibrating Screen

Mining & Mineral Processing – Screens iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Quarrying & Aggregates – Ideal for.

Learn More

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More