With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Applications

Gold Ore Crusher

The Critical Role of Crushing in Gold Ore Processing

Gold extraction demands precise size reduction to liberate precious minerals from hard rock. As a leading manufacturer of mining crushing equipment, Liming Heavy Industry provides robust Gold Ore Crusher engineered for high efficiency in demanding conditions, from large-scale mines to compact operations.

Stage 1: Primary Crushing – Reducing Run-of-Mine (ROM) Ore

- Challenge: Gold-bearing rock (typically 500–1500mm) requires initial size reduction.

- Solution: Heavy-duty Jaw Crusher with deep crushing chambers and high torque.

Liming Equipment:- PE Series Jaw Crusher (e.g., PE600×900, PE750×1060)

- High reduction ratio (6:1) for quartz-rich gold ore

- Reinforced toggle plate for shock absorption

- C6X Series Jaw Crusher (e.g., C6X100, C6X145)

- Modular design for abrasive ores

- 30% higher capacity vs conventional crushers

- PE Series Jaw Crusher (e.g., PE600×900, PE750×1060)

Stage 2: Secondary Crushing – Precision Size Control

- Challenge: Producing uniform 20–50mm feed for grinding circuits.

- Solution: Hydraulic Cone Crusher for inter-particle crushing and cubical output.

Liming Equipment:- HPT Multi-cylinder Cone Crusher (e.g., HPT200, HPT400)

- Laminated crushing for high-grade vein gold ore

- Automated hydraulic adjustment system

- HST Single Cylinder Cone Crusher (e.g., HST160, HST315)

- Compact design for CIP/CIL plant integration

- 25% lower energy consumption

- HPT Multi-cylinder Cone Crusher (e.g., HPT200, HPT400)

Stage 3: Tertiary/Fine Crushing – Optimizing Liberation

- Challenge: Achieving ≤10mm particle size for maximum gold recovery.

- Solution:Vertical Shaft Impact (VSI) Crusher for selective fragmentation.

Liming Equipment:- VSI6X Sand Maker (e.g., VSI6X1263)

- Rotor centrifugal technology for refractory gold ores

- 60% reduction in grinding costs

- VSI6X Sand Maker (e.g., VSI6X1263)

Supporting Technology: Screening & Material Handling

- S5X Vibrating Screen (e.g., S5X1860-3)

- 3-layer design for precise classification

- B6X Belt Conveyor

- Sealed structure for dust control in cyanidation plants

Why Liming Gold Ore Crusher Deliver Superior Value

- Wear Resistance

- Manganese steel jaws/cones with ceramic inserts (HPT series) for quartzite ore

- Energy Efficiency

- HST Cone Crushers reduce power consumption by 15–25%

- Modular Flexibility

- Mobile crushing stations (e.g., K3 Series) for remote artisanal mines

- Recovery Optimization

- VSI6X produces fractured grains enhancing leaching kinetics

Technical Comparison: Liming Gold Crushing Solutions

| Equipment Type | Key Model | Gold Ore Application | Output Size |

|---|---|---|---|

| Primary Crusher | C6X160 | Hard rock (quartz veins) | 150–250mm |

| Secondary Crusher | HPT300 | Sulfide gold ore | 25–50mm |

| Tertiary Crusher | VSI6X1263 | Oxide ore/Heap leach feed | 3–10mm |

Partner with Liming for Your Gold Operation

“Over 80% of liberated gold occurs at ≤75μm – optimal crushing is the first step to profitability.” – Liming Process Engineering Team

We engineer site-specific circuits including:

- Hard Rock Gold Plants: C6X + HPT + VSI6X configuration

- Alluvial/Eluvial Systems: Mobile K3-1585 Plant with integrated screen

Request Your Gold Ore Test Crushing Report

→ Contact Liming engineers for a free ore analysis and circuit design proposal using PE/C6X Jaw Crushers, HPT/HST Cone Crushers, and VSI6X Impact Crushers.

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

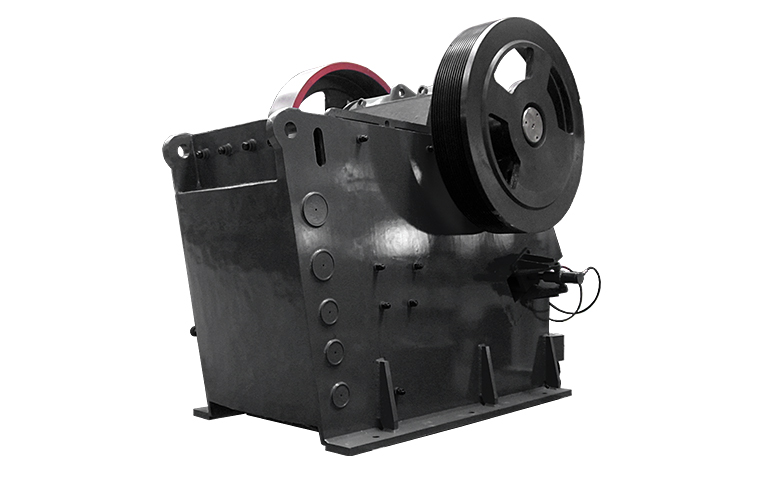

PE Jaw Crusher

Ideal for primary crushing of various materials: Mining/Ore Processing: Crushing gold, copper, iron ore, and manganese. Aggregates & Construction: Granite, basalt, limestone,.

Learn More

PEW Jaw Crusher

Mining: Ideal for primary crushing of hard ores (gold, iron, copper) and abrasive rocks. Quarrying: Efficiently processes granite, basalt, and other aggregates.

Learn More

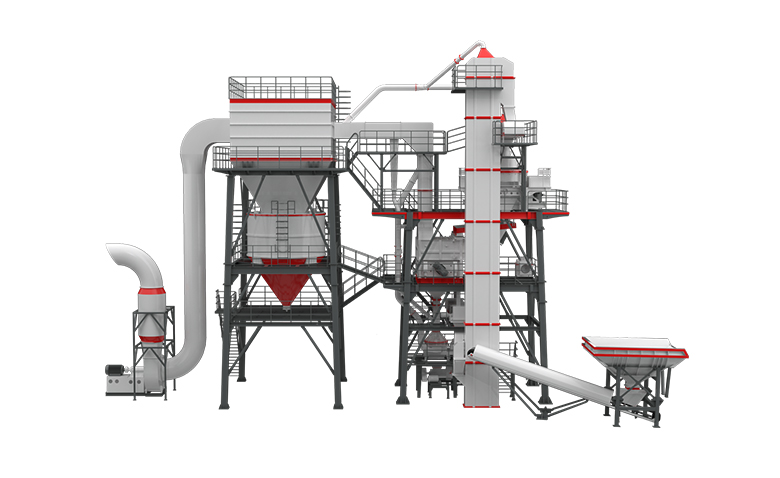

VUS Aggregate Optimization System

Sand & Gravel Production – Produces high-purity machine-made sand for concrete, asphalt, and dry-mix mortar. Sludge & Tailings Recycling – Recovers fine.

Learn More

C5X Jaw Crusher

Mining & Ore Processing Ideal for primary crushing of iron ore, gold ore, copper ore, and other metallic/non-metallic minerals. Handles tough materials.

Learn More

HPT Hydraulic Cone Crusher

Mining & Quarrying: Crushing hard rocks (granite, basalt, iron ore) with high reduction ratios. Aggregate Production: Producing cubic-shaped end products for construction.

Learn More

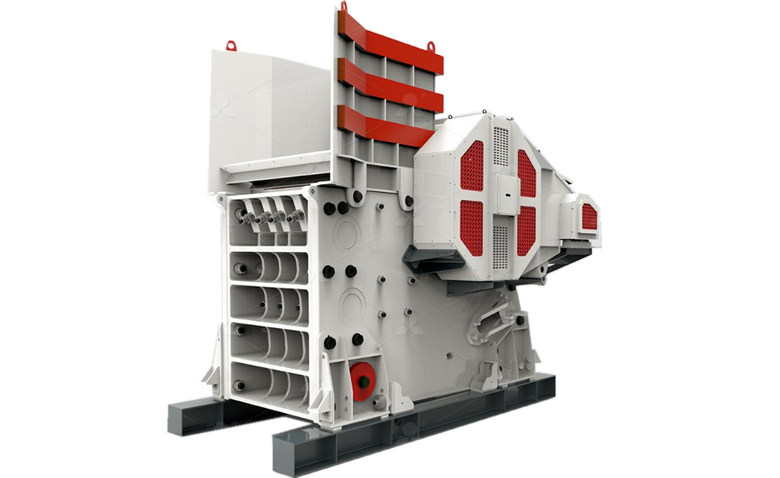

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More