With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Applications

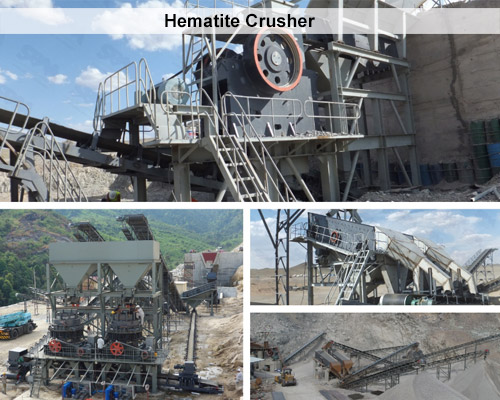

Hematite Crusher

Hematite Mining & Crushing Process

Hematite, a primary iron ore, requires efficient crushing to maximize iron yield. Liming Heavy Industry provides robust hematite crushers tailored for high-capacity mining operations.

1. Hematite Mining

Hematite is extracted via open-pit or underground mining. The ore is drilled, blasted, and transported to crushing plants for processing.

2. Hematite Crushing Equipment

Our hematite crushing line utilizes a multi-stage process with precision-engineered crushers:

- Primary Crushing (Coarse Hematite Crusher)

- C6X Jaw Crusher: High crushing ratio for raw hematite (≤1,200mm), reducing ore to ≤300mm.

- PEW European Jaw Crusher: Ideal for abrasive hematite with hydraulic adjustment.

- Secondary Crushing (Medium/Fine Hematite Crusher)

- HPT Multicylinder Hydraulic Cone Crusher: Processes hematite to ≤70mm with automated cavity clearing.

- CI5X Impact Crusher: For cubical hematite aggregates, ideal for pelletizing feed.

- Tertiary Crushing & Shaping

- VSI6X Sand Maker: Produces uniform hematite sand (0-5mm) for sintering.

3. Supporting Equipment

- S5X Vibrating Screen: Classifies crushed hematite by size.

- B6X Belt Conveyor: Transports ore between crushing stages.

Why Choose Liming’s Hematite Crushers?

- High Efficiency: Reduced downtime with wear-resistant materials.

- Custom Solutions: Configured for hematite’s abrasiveness and moisture content.

- EPC Services: Full hematite processing plant design and installation.

Upgrade Your Hematite Processing – Contact Liming Heavy Industry for a customized hematite crusher solution today!

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

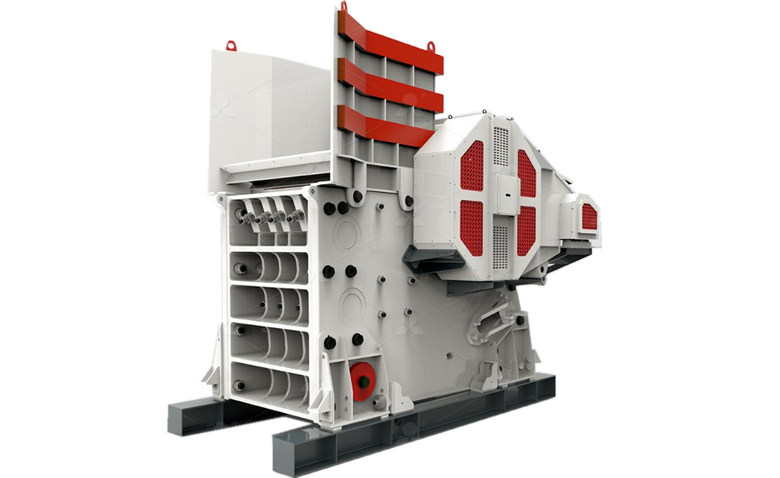

PF Impact Crusher

Mining: Crushing iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregates: Processing limestone, granite, concrete, and construction waste for road/base.

Learn More

C5X Jaw Crusher

Mining & Ore Processing Ideal for primary crushing of iron ore, gold ore, copper ore, and other metallic/non-metallic minerals. Handles tough materials.

Learn More

PE Jaw Crusher

Ideal for primary crushing of various materials: Mining/Ore Processing: Crushing gold, copper, iron ore, and manganese. Aggregates & Construction: Granite, basalt, limestone,.

Learn More

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More

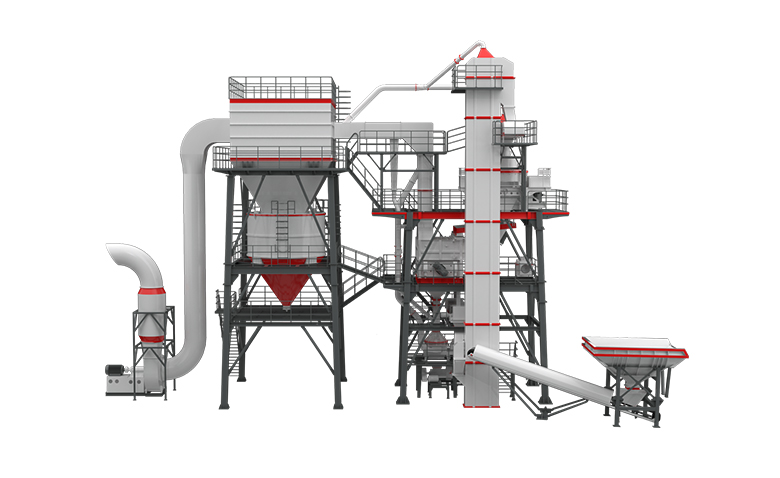

VUS Aggregate Optimization System

Sand & Gravel Production – Produces high-purity machine-made sand for concrete, asphalt, and dry-mix mortar. Sludge & Tailings Recycling – Recovers fine.

Learn More

HST Hydraulic Cone Crusher

The HST Hydraulic Cone Crusher is ideal for: Mining: Efficient crushing of ores (iron, copper, gold, etc.) Quarrying: Processing hard rocks (granite,.

Learn More