With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Applications

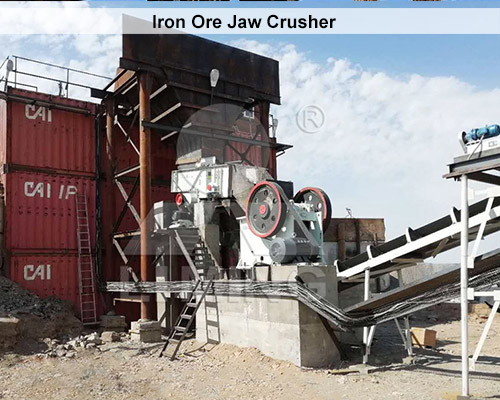

Iron Ore Crusher

The Critical Role of Crushing in Iron Ore Beneficiation

Iron ore processing demands rugged, high-capacity crushing equipment to handle abrasive hematite (Fe₂O₃) and magnetite (Fe₃O₄) ores. Liming Heavy Industry designs Iron Ore Crusher specifically engineered for:

- Throughput capacities up to 8,000 TPH

- Ore hardness up to 300 MPa UCS

- Feed sizes ≤ 1,500mm

Stage 1: Primary Crushing – ROM Ore Reduction

- Challenge: Breaking massive iron ore lumps with high abrasiveness

- Solution:Gyratory/Jaw Crusher with reinforced structures

Liming Equipment:- HGT Gyratory Crusher (e.g. HGT1385)

- ≤1,500mm feed size for Australian Pilbara ore

- 40% higher capacity vs traditional gyratories

- C6X Jaw Crusher (e.g. C6X160)

- ≤1,000mm feed opening

- MX manganese jaws with 3x lifespan

- HGT Gyratory Crusher (e.g. HGT1385)

Stage 2: Secondary Crushing – Size Reduction

- Challenge: Reducing ore to 30-50mm for AG/SAG mill feed

- Solution:Hydraulic Cone Crusher

Liming Equipment:- HPT Multi-Cylinder Cone Crusher (e.g. HPT500)

- Laminated crushing for taconite processing

- Automatic iron discharge system

- HST Cone Crusher (e.g. HST315)

- ≤25mm output for pellet feed preparation

- HPT Multi-Cylinder Cone Crusher (e.g. HPT500)

Stage 3: Tertiary Crushing – Fines Generation Control

- Challenge: Producing 6-10mm sinter feed with minimal slimes

- Solution:Fine Cone Crusher with precision settings

Liming Equipment:- HPT300 Fine Cavity

- Hydraulic CSS adjustment (±1mm)

- -0.075mm generation <12%

- HPT300 Fine Cavity

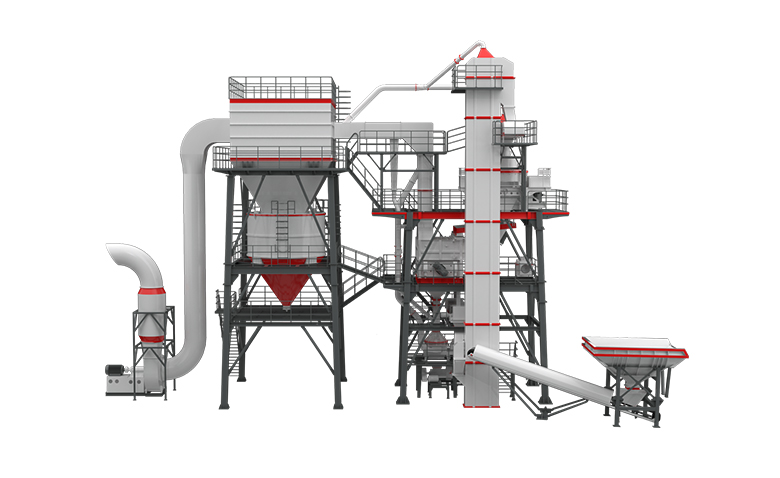

Integrated Material Handling

- S5X Heavy-Duty Screen (e.g. S5X3075-3)

- 3,500 TPH capacity for scalping

- B6X Belt Conveyor

- Impact idlers for 200mm lump protection

Technical Advantages for Iron Ore Applications

| Feature | Operational Benefit |

|---|---|

| Patented MX Alloy | 22,000 MT wear life in hematite |

| Intelligent Control System | Real-time throughput optimization |

| Dust Suppression | <5mg/m³ in crushing cavity |

| Modular Design | 72hr primary crusher relocation |

Plant Configurations by Iron Ore Type

Brazilian 5,500TPH Project Data:

- Ore: Hematite (Abrasion Index 0.38)

- Final Product: 92% <32mm

- Wear Cost: $0.003/ton for HPT600 mantles

Why Top Iron Miners Choose Liming

“Our HGT gyratory handles 6,200 TPH of Pilbara ore – 30% higher than industry average with 18% lower OPEX.”

– Liming Mining Engineer

Tailored Solutions for:

- DSO Operations: Mobile K3-3785 Plant

- Ultra-Hard Magnetite: HPT + HST circuit

- Integrated Plants: Complete crushing/screening systems

Free Ore Test Crushing:

→ Submit samples for grindability testing

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

VUS Aggregate Optimization System

Sand & Gravel Production – Produces high-purity machine-made sand for concrete, asphalt, and dry-mix mortar. Sludge & Tailings Recycling – Recovers fine.

Learn More

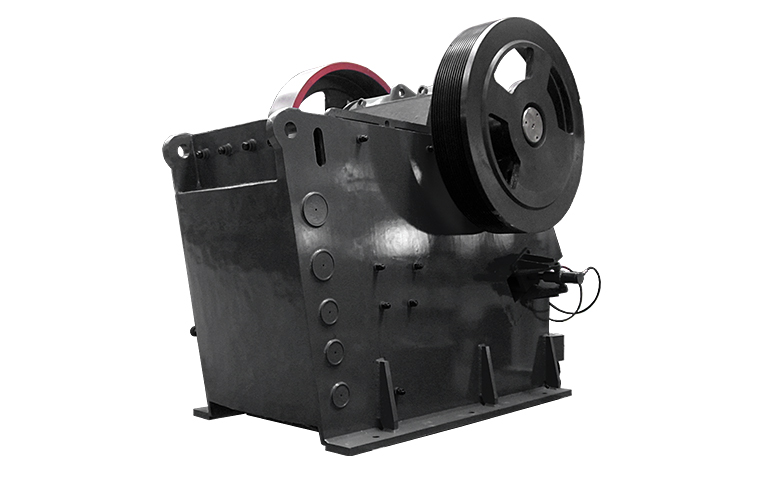

C5X Jaw Crusher

Mining & Ore Processing Ideal for primary crushing of iron ore, gold ore, copper ore, and other metallic/non-metallic minerals. Handles tough materials.

Learn More

PEW Jaw Crusher

Mining: Ideal for primary crushing of hard ores (gold, iron, copper) and abrasive rocks. Quarrying: Efficiently processes granite, basalt, and other aggregates.

Learn More

HPT Hydraulic Cone Crusher

Mining & Quarrying: Crushing hard rocks (granite, basalt, iron ore) with high reduction ratios. Aggregate Production: Producing cubic-shaped end products for construction.

Learn More

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More

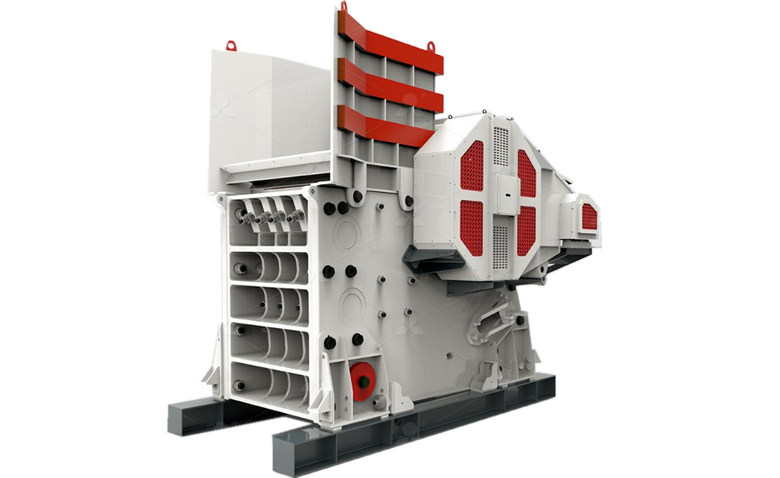

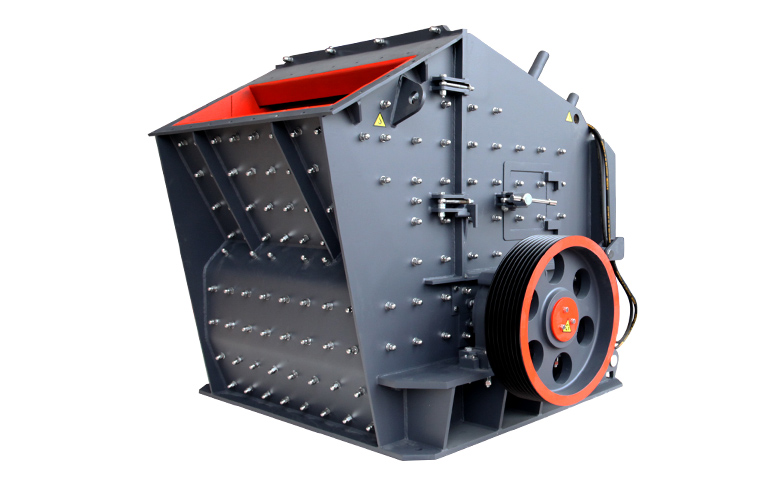

PFW Impact Crusher

Mining & Quarrying: Efficiently crushes ores (gold, iron, copper) and aggregates. Construction: Processes limestone, concrete, and demolition waste for road/base materials. Recycling:.

Learn More