With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Applications

Lithium Ore Crusher

Precision Crushing for Lithium Battery Raw Materials

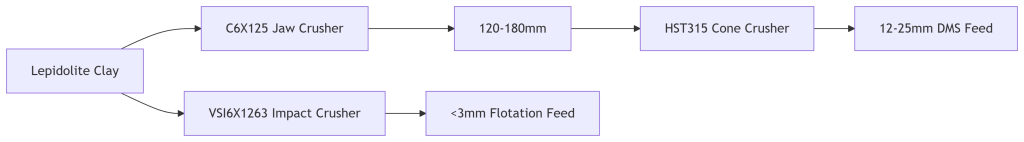

With surging demand for battery-grade lithium, efficient liberation of spodumene (LiAlSi₂O₆) and lepidolite from hard pegmatite ores (UCS 150-250 MPa) is critical. Liming Heavy Industry designs Lithium Ore Crusher that minimize fines generation – preserving +0.3mm particles vital for dense media separation (DMS).

Stage 1: Primary Crushing – Pegmatite Reduction

- Challenge: Breaking coarse-crystalline ore (≤600mm) with low iron contamination

- Solution:Jaw Crusher with ceramic-lined crushing chambers

Liming Equipment:- C6X Series Jaw Crusher (e.g. C6X125)

- ≤430mm feed size for Australian Greenbushes-type ore

- 316L stainless steel frame for corrosive environments

- PE Series Jaw Crusher (e.g. PE900×1200)

- ≤180mm output with <3% -10mm fines

- C6X Series Jaw Crusher (e.g. C6X125)

Stage 2: Secondary Crushing – Selective Liberation

- Challenge: Preserving coarse spodumene crystals (1-20mm) for DMS

- Solution:Single Cylinder Cone Crusher with inter-particle crushing

Liming Equipment:- HST Series Cone Crusher (e.g. HST250)

- ≤25mm product with cubicle shape

- 30% lower fines vs multi-cylinder designs

- HPT Series Cone Crusher (e.g. HPT300 Fine Cavity)

- 8-12mm output for flotation feed

- HST Series Cone Crusher (e.g. HST250)

Stage 3: Tertiary Crushing – Fines Control

- Challenge: Minimizing slimes in lepidolite clays

- Solution:Vertical Shaft Impact Crusher with grinding path control

Liming Equipment:- VSI6X Sand Maker (e.g. VSI6X1263)

- Rotor speed adjustable 900-1500 rpm

- -0.075mm generation <15%

- VSI6X Sand Maker (e.g. VSI6X1263)

Integrated Classification Systems

- S5X Vibrating Screen (e.g. S5X1860-3)

- Polyurethane screens for 0.3/1/3mm cut points

- LUM Ultrafine Mill (Optional for clay-rich ores)

Technical Advantages for Lithium Applications

| Feature | Benefit |

|---|---|

| Ceramic Wear Protection | <0.01% Fe contamination |

| Intelligent Speed Control | Real-time fines optimization |

| Modular Screen Decks | Quick DMS/Flotation feed switching |

| Zero-Dust Sealing | Critical for battery-grade Li₂CO₃ |

Plant Configuration for Lithium Ore Types

Performance Data (Zimbabwe 300TPH Plant):

- Ore: Petalite-spodumene blend (UCS 180 MPa)

- Product: 92% 0.3-6mm (ideal for DMS)

- Fe Contamination: ≤0.008%

Why Global Lithium Miners Choose Liming

“Over-crushing spodumene reduces DMS recovery by 20-35% – our HST crushers preserve critical +0.3mm fraction.”

– Liming Battery Minerals Engineer

Tailored Solutions for:

- Hard Rock Lithium: C6X + HST circuit

- Sedimentary Clays: Mobile K3-2585 Plant with VSI6X

- Complex Pegmatites: HPT fine-crushing for tantalum co-recovery

Free Lithium Ore Test Crushing:

→ Submit 50kg samples for size distribution analysis

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

HST Hydraulic Cone Crusher

The HST Hydraulic Cone Crusher is ideal for: Mining: Efficient crushing of ores (iron, copper, gold, etc.) Quarrying: Processing hard rocks (granite,.

Learn More

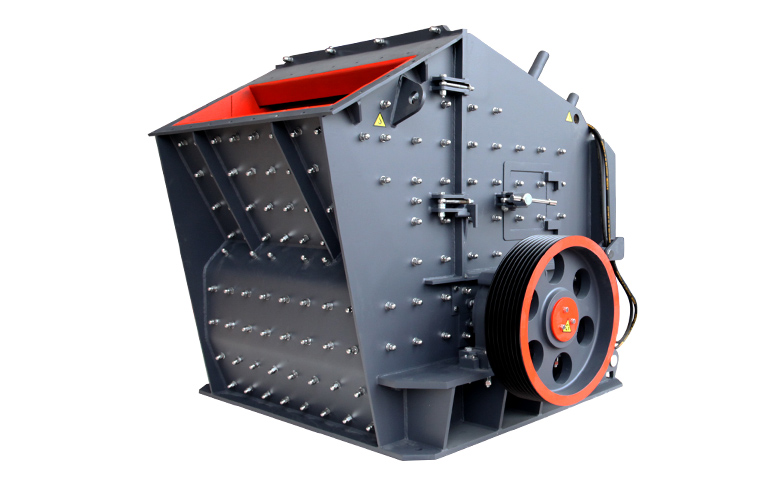

PFW Impact Crusher

Mining & Quarrying: Efficiently crushes ores (gold, iron, copper) and aggregates. Construction: Processes limestone, concrete, and demolition waste for road/base materials. Recycling:.

Learn More

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More

CI5X Impact Crusher

The CI5X Impact Crusher is widely used in: Quarry & Mining Operations – Crushing aggregates, limestone, dolomite, and more Recycling – Processing.

Learn More

VSI6X Sand Making Machine

Construction: Produces high-grade sand for concrete, asphalt, and ready-mix plants. Mining: Processes iron ore, gold ore, and non-metallic minerals into fine aggregates..

Learn More

HPT Hydraulic Cone Crusher

Mining & Quarrying: Crushing hard rocks (granite, basalt, iron ore) with high reduction ratios. Aggregate Production: Producing cubic-shaped end products for construction.

Learn More