Introduction

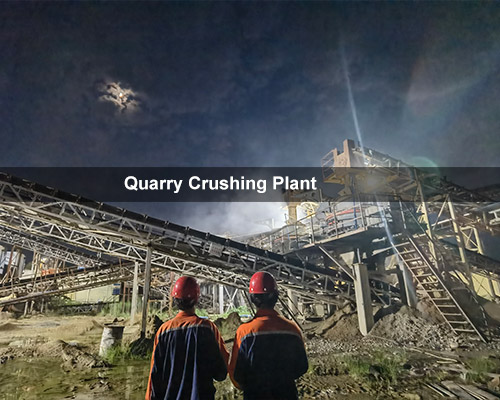

In the mining and construction industries, rock crushing is a crucial process that transforms raw quarry materials into usable aggregates for various applications. Hiring professional rock crushing contractors ensures optimal efficiency, productivity, and compliance with safety and environmental regulations. This guide explores the role of rock crushing contractors in quarry operations, key services they offer, and how to choose the best contractor for your needs.

Why Hire Professional Rock Crushing Contractors?

1. Expertise and Experience

Professional contractors bring years of expertise in rock crushing, ensuring efficient processing of hard materials like granite, limestone, and basalt.

2. Cost-Effective Solutions

Instead of investing in expensive equipment, renting a contractor’s services reduces operational and maintenance costs.

3. Customized Crushing Solutions

Contractors tailor their operations to meet specific quarry requirements, including primary, secondary, and tertiary crushing stages.

4. Safety and Regulatory Compliance

Reputable contractors adhere to OSHA and environmental regulations, minimizing risks and preventing legal complications.

Key Services Offered by Rock Crushing Contractors

1. Primary Crushing (Jaw & Gyratory Crushers)

- Processes large raw rocks into manageable sizes.

- Ideal for hard, abrasive materials.

2. Secondary & Tertiary Crushing (Cone & Impact Crushers)

- Further reduces material size for finer aggregates.

- Produces uniform particles for construction and road base applications.

3. Mobile Crushing Solutions

- Perfect for temporary or remote quarry sites.

- Minimizes transportation costs.

4. Screening and Material Sorting

- Uses vibrating screens to separate different aggregate sizes.

- Ensures only high-quality materials proceed for further processing.

5. Material Handling & Stockpiling

- Contractors manage conveyor systems, loaders, and stockpile organization.

Choosing the Right Rock Crushing Contractor

Equipment Quality

Look for contractors using modern crushers like jaw crushers, cone crushers, and impact crushers from reputable brands.

Track Record & References

Ask for case studies from past quarry projects to assess reliability.

Environmental Practices

Ensure contractors follow sustainable crushing methods, including dust suppression and noise control.

Contract Flexibility

Choose contractors offering short-term or long-term agreements based on your operational needs.

Conclusion

Hiring experienced rock crushing contractors is essential for maximizing quarry productivity and minimizing operational costs. Whether you need a fixed crushing plant or mobile crushers, the right contractor ensures seamless material processing while maintaining environmental compliance.