Introduction

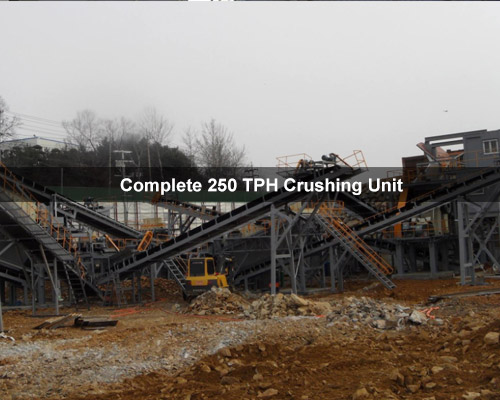

A well-designed 250 TPH (tonnes per hour) crushing unit is essential for large-scale aggregate production in quarries, mining, and construction projects. This article explores the key components, configurations, and costs of a complete 250 TPH crushing plant optimized for high-efficiency aggregate output.

Why Choose a 250 TPH Crushing Plant?

A 250 TPH crushing unit balances high productivity and manageable investment, making it ideal for:

- Large-scale aggregate production (e.g., road construction, concrete supply).

- Quarry operations needing steady material processing.

- Mining & recycling projects requiring durable rock crushing solutions.

Key Components of a 250 TPH Crushing Unit

1. Primary Crushing (Jaw Crusher)

- Recommended Model: C6X Jaw Crusher (or equivalent)

- Feed Size: Up to 900mm

- Output Size: ~ 150-200mm

- Power: 160-200 kW

2. Secondary Crushing (Cone Crusher)

- Recommended Model: HPT Multi-Cylinder Hydraulic Cone Crusher

- Feed Size: ~ 150-200mm

- Output Size: 30-60mm (adjustable for different aggregates)

- Power: 250-315 kW

3. Tertiary Crushing (Vertical Shaft Impact Crusher – for shaping)

- Recommended Model: VSI6X Sand Maker

- Input Size: < 50mm

- Output Size: 0-5mm (manufactured sand) or 5-20mm (crushed stone)

- Power: 220-315 kW

4. Screening & Grading (Vibrating Screens)

- Recommended Model: S5X Heavy-Duty Vibrating Screen

- Decks: 2-3 layers (for precise gradation)

- Output Sizes: 0-5mm, 5-10mm, 10-20mm, 20-40mm

5. Conveyors & Feeders

- Belt Width: 800-1200mm (for efficient material flow)

- Feeders: F5X Heavy-Duty Grizzly Feeder (to regulate input)

Typical Configuration for 250 TPH Aggregate Plant

| Stage | Equipment | Model Example | Output Size |

|---|---|---|---|

| Primary | Jaw Crusher | C6X Series | 150-200mm |

| Secondary | Cone Crusher | HPT300 | 30-60mm |

| Tertiary | VSI Crusher | VSI6X1263 | 0-5mm (sand) / 5-20mm (gravel) |

| Screening | Vibrating Screen | S5X2460-3 | Multiple fractions |

Production Output & Aggregate Grading

A well-optimized 250 TPH crushing plant can produce:

- 150 TPH of 5-20mm gravel (ideal for concrete & asphalt mixes)

- 70 TPH of 0-5mm manufactured sand (for high-grade construction)

- 30 TPH of 20-40mm stone (used in road base layers)

Cost Breakdown for 250 TPH Crushing Unit

| Component | Estimated Cost (USD) |

|---|---|

| Jaw Crusher | $150,000 – $200,000 |

| Cone Crusher | $200,000 – $250,000 |

| VSI Crusher | $180,000 – $220,000 |

| Screening System | $100,000 – $150,000 |

| Conveyors & Feeders | $80,000 – $120,000 |

| Total Setup Cost | $700,000 – $900,000+ |

(Note: Prices vary based on brand, automation, and additional features.)

Optimizing Your 250 TPH Crushing Plant

- Automation: Use PLC control for consistent production & reduced downtime.

- Dust Suppression: Install water spray or bag filters for environmental compliance.

- Preventive Maintenance: Regular inspections to maximize crusher lifespan.

- Portable vs. Stationary: Consider mobile crushers if relocating frequently.

A 250 TPH crushing plant is a robust solution for high-volume aggregate production. By selecting the right jaw crusher, cone crusher, VSI, and screening setup, operators can achieve efficient, high-quality output for construction and industrial applications. For customized setups, consult professional crushing plant suppliers to match your project’s exact requirements.