With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Projects

25-50 TPH Basalt Crushing Plant In Vietnam

Client Profile

A leading construction materials supplier in Vietnam needed a reliable 25-50 TPH basalt sand and gravel production line to support infrastructure development. The customer required high-quality aggregates with a consistent particle size for concrete and road construction.

Project Overview

- Location: Vietnam

- Material: Basalt

- Capacity: 25-50 TPH

- Final Product: 0-5mm sand, 5-10mm, 10-20mm gravel

- Application: Construction, concrete, and road building

Challenges

- High Hardness Material: Basalt is an extremely hard and abrasive rock, requiring durable crushing equipment.

- Stable Output Demand: The customer needed a steady 25-50 TPH output with minimal downtime.

- Fine Sand Production: The project required high-quality manufactured sand (0-5mm) for construction use.

Solution: Liming Heavy Industry’s Advanced Crushing Line

1. Primary Crushing – C6X Jaw Crusher

- Model: C6X125

- Input Size: ≤500mm

- Output Size: 100-150mm

- Role: Pre-crushing basalt for secondary reduction

- Advantage: High crushing efficiency, robust wear resistance for hard materials.

2. Secondary Crushing – HPT Hydraulic Cone Crusher

- Model: HPT200

- Input Size: ≤150mm

- Output Size: 30-50mm

- Role: Intermediate crushing for sand preparation

- Advantage: Multi-cylinder hydraulic system for finer output and energy savings.

3. Sand Making – VSI6X Sand Maker

- Model: VSI6X1150

- Input Size: ≤50mm

- Output Size: 0-5mm (adjustable)

- Role: High-quality sand production for concrete and mortar

- Advantage: Impeller wear-resistant design, low noise, high sand yield.

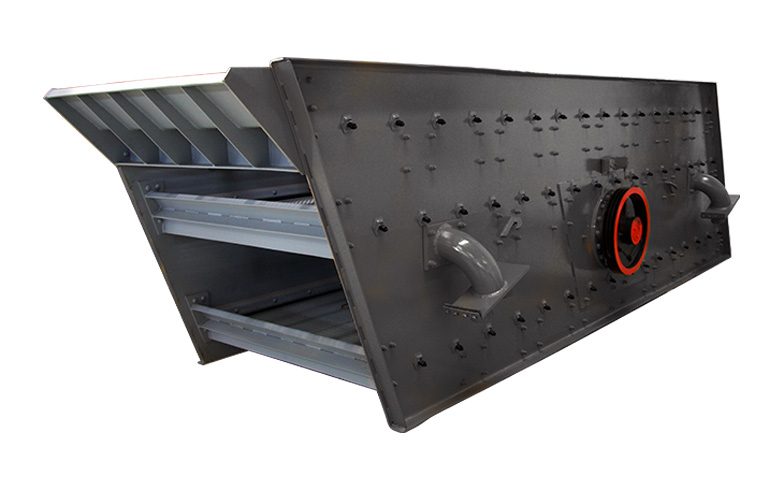

4. Screening – Vibrating Screen (YKN Series)

- Model: YKN2460

- Role: Efficient screening into different sizes (5-10mm, 10-20mm)

- Advantage: Stable performance, high screening capacity.

Technical Highlights

- Automated Control System – Ensures smooth operation with minimal manual intervention.

- Durable Wear Parts – Extended service life for basalt crushing.

- Energy-Efficient Design – Lower power consumption compared to traditional crushers.

Project Results

- High Production Efficiency: Achieved 50 TPH maximum output.

- Premium Sand Quality: 0-5mm sand meets ISO sand standard for concrete.

- Low Maintenance Costs: Long-lasting components reduced operational expenses.

- Customizable Setting: Output size adjustable to meet different market demands.

Customer Feedback

“Liming’s basalt crushing line operates smoothly with excellent sand production. The VSI6X sand maker and HPT cone crusher are efficient and reliable. Thanks to Liming for delivering a high-performance solution!”

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More

HPT Hydraulic Cone Crusher

Mining & Quarrying: Crushing hard rocks (granite, basalt, iron ore) with high reduction ratios. Aggregate Production: Producing cubic-shaped end products for construction.

Learn More

YKN Vibrating Screen

Mining & Minerals: Ideal for grading coal, iron ore, copper, and gold ore. Aggregates & Sand: Efficiently screens crushed stone, gravel, and.

Learn More

VSI6X Sand Making Machine

Construction: Produces high-grade sand for concrete, asphalt, and ready-mix plants. Mining: Processes iron ore, gold ore, and non-metallic minerals into fine aggregates..

Learn More