With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Projects

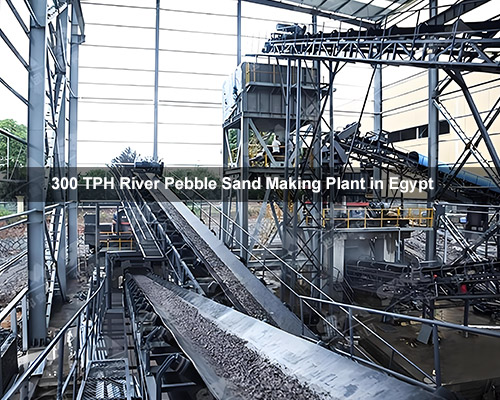

300 TPH River Pebble Sand Making Plant in Egypt

Client Profile:

Our client is a leading construction materials producer in Egypt, specializing in high-grade aggregates for infrastructure and commercial projects. They needed a reliable sand-making solution to process river pebbles into premium-quality sand for concrete production.

Project Overview:

- Location: Egypt

- Raw Material: River pebbles (hardness: 6-7 Mohs)

- Required Output: 300 tons per hour

- Final Product: High-quality manufactured sand (0-5mm) for concrete mixing

Challenges:

- High Hardness Material: River pebbles are hard and abrasive, requiring durable crushing equipment.

- Strict Gradation: The client demanded precise sand gradation for optimal concrete strength.

- Dust Control: Egypt’s arid climate required effective dust suppression measures.

Solution: Customized Sand Making Line by Liming Heavy Industry

Equipment Configuration & Benefits:

- Primary Crushing: C6X Jaw Crusher

- Handles large-sized (>500mm) river pebbles efficiently.

- Deep crushing chamber ensures high throughput (300TPH).

- Secondary Crushing: HPT Multi-Cylinder Hydraulic Cone Crusher

- Provides stable intermediate crushing (50-100mm).

- Hydraulic adjustment ensures uniform product size.

- Tertiary Crushing & Sand Shaping: VSI6X Sand Maker

- Produces well-graded sand (0-5mm) with cubical shape.

- Advanced rotor design reduces wear costs in abrasive pebble crushing.

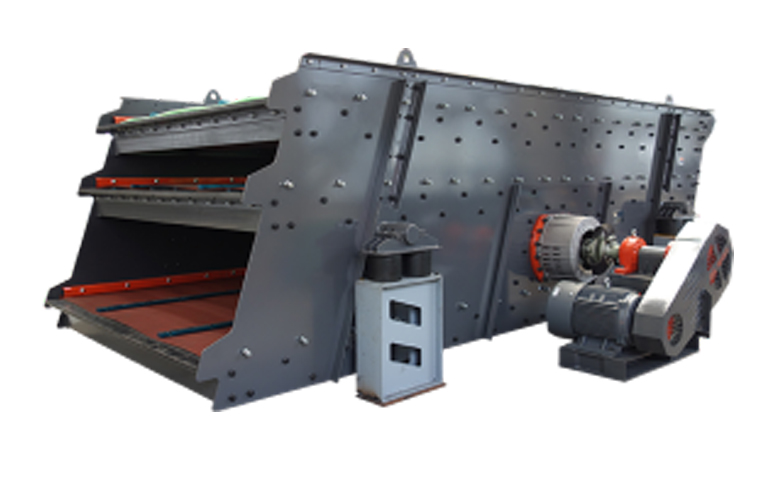

- Screening: S5X Vibrating Screen

- Multi-layer screening ensures precise particle separation.

- High-frequency vibration prevents clogging.

- Dust Control: Pulse Dust Collector

- Minimizes airborne particles, complying with Egypt’s environmental regulations.

Technical Highlights:

- Automated Control System: Real-time monitoring optimizes production efficiency.

- Wear-Resistant Components: Tungsten carbide liners extend equipment lifespan.

- Energy Efficiency: HPT Cone Crusher and VSI6X reduce power consumption by 20%.

Project Results:

- Output Achieved: 320TPH (exceeding target capacity).

- Sand Quality: Cubical particles with ≤3% silt content, ideal for concrete.

- Low Maintenance: Only 8 hours/month downtime for wear parts replacement.

Client Feedback:

“Liming’s sand-making line delivers outstanding performance in Egypt’s tough conditions. The VSI6X’s low wear rate and high sand yield have significantly boosted our profitability.” — Mohamed Ali, Project Manager

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More

S5X Vibrating Screen

Mining & Mineral Processing – Screens iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Quarrying & Aggregates – Ideal for.

Learn More

VSI6X Sand Making Machine

Construction: Produces high-grade sand for concrete, asphalt, and ready-mix plants. Mining: Processes iron ore, gold ore, and non-metallic minerals into fine aggregates..

Learn More