With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Projects

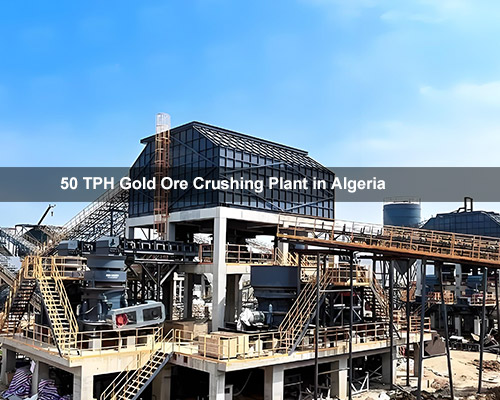

50 TPH Gold Ore Crushing Plant in Algeria

Client Overview

Our client is a leading mining company in Algeria specializing in gold extraction. Facing increasing demand for high-quality ore processing, they sought a reliable crushing solution capable of handling 50 tons per hour (TPH) of gold ore with minimal downtime and maintenance.

Project Background

- Location: Algeria

- Material: Gold ore (medium-hard rock)

- Required Capacity: 50 TPH

- Final Product: 0-20mm uniformly crushed ore

Challenges

- Hard Rock Crushing: Gold ore’s abrasive nature demanded durable equipment.

- High Efficiency Requirement: Needed consistent 50TPH output without clogging.

- Space Constraints: Compact plant layout was essential for remote site deployment.

- Maintenance Concerns: Minimizing operational downtime in harsh desert conditions.

Solution: Liming Heavy Industry’s Proven Mining Equipment

After evaluating the client’s needs, we recommended a customized crushing line featuring:

Core Equipment & Advantages

- Primary Crushing – JC Series Jaw Crusher

- Role: Coarse crushing of raw gold ore (<500mm) into smaller chunks.

- Advantages: High crushing ratio, robust structure, and hydraulic adjustment for quick setting changes.

- Secondary Crushing – HPT Hydraulic Cone Crusher

- Role: Fine crushing to produce 0-20mm uniform particles for optimal gold recovery.

- Advantages: Multi-cylinder hydraulic design reduces wear, auto-overload protection, and energy-saving performance (>15% vs Traditional cone crusher).

- Screening – S5X Vibrating Screen

- Role: Precise classification to separate oversized material for re-crushing.

- Advantages: Heavy-duty structure, high screening efficiency (>90%), and low noise.

- Supporting Equipment: Belt conveyors, dust suppression system, and electric control panel for seamless integration.

Technical Highlights

- Automation: PLC-controlled system monitors real-time performance and alerts operators to anomalies.

- Durability: Tungsten carbide wear parts extend service life in abrasive gold ore processing.

- Modular Design: Plug-and-play components reduced on-site installation time by 30%.

Project Results

- Achieved 50–55 TPH steady output (exceeding target by 10%).

- Uniform 0-20mm product size improved downstream gold recovery rates.

- 30% lower maintenance costs thanks to HPT crusher’s hydraulic clearing system.

- Zero environmental violations with integrated dust control.

Client Testimonial

“Liming Heavy Industry’s team delivered a turnkey solution that met our strict deadlines. The HPT cone crusher’s reliability in Algeria’s harsh climate has been outstanding, and the S5X screen’s precision reduced waste. We plan to expand our collaboration!”

— Project Manager, Algerian Mining Company

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

C5X Jaw Crusher

Mining & Ore Processing Ideal for primary crushing of iron ore, gold ore, copper ore, and other metallic/non-metallic minerals. Handles tough materials.

Learn More

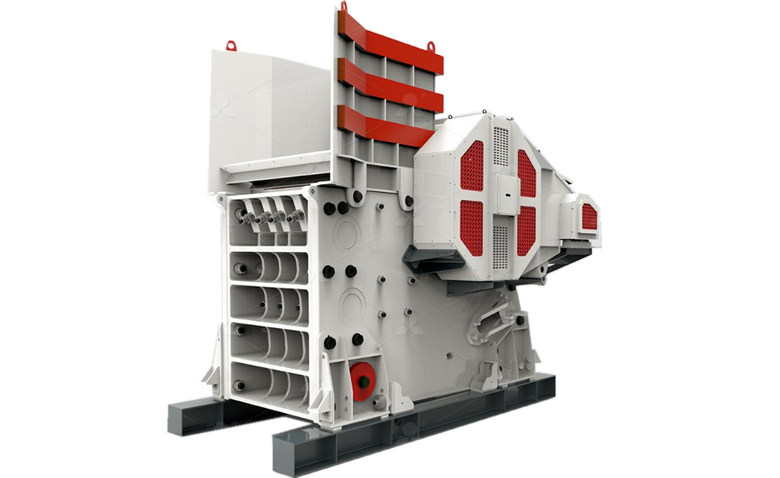

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More

HST Hydraulic Cone Crusher

The HST Hydraulic Cone Crusher is ideal for: Mining: Efficient crushing of ores (iron, copper, gold, etc.) Quarrying: Processing hard rocks (granite,.

Learn More

HPT Hydraulic Cone Crusher

Mining & Quarrying: Crushing hard rocks (granite, basalt, iron ore) with high reduction ratios. Aggregate Production: Producing cubic-shaped end products for construction.

Learn More

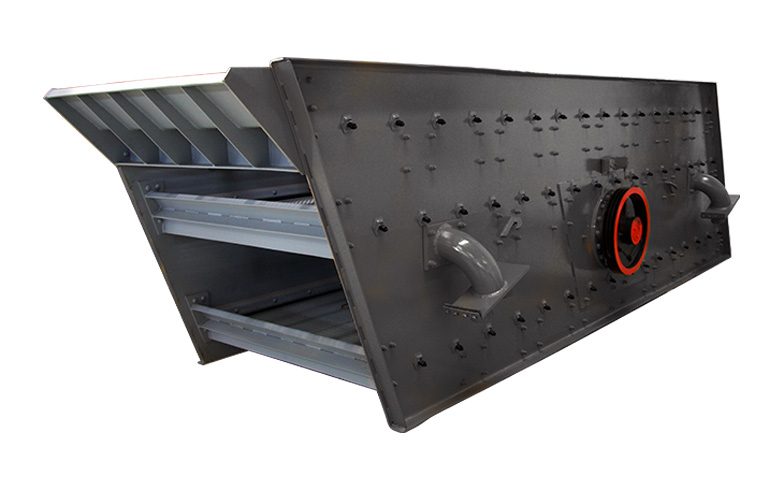

YKN Vibrating Screen

Mining & Minerals: Ideal for grading coal, iron ore, copper, and gold ore. Aggregates & Sand: Efficiently screens crushed stone, gravel, and.

Learn More

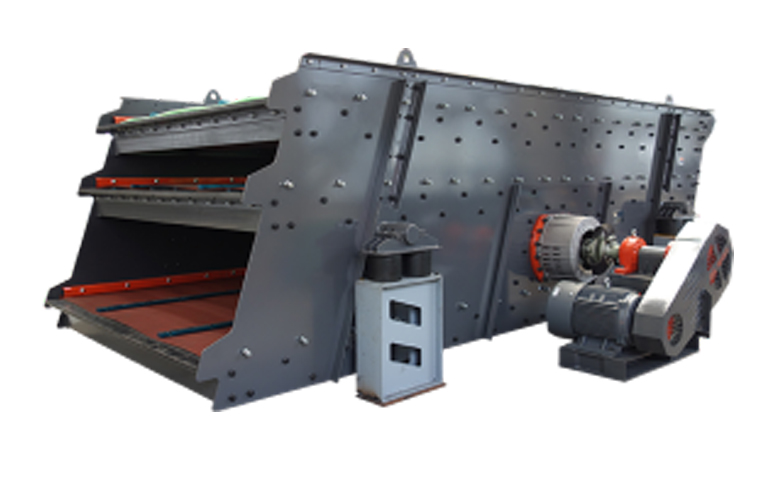

S5X Vibrating Screen

Mining & Mineral Processing – Screens iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Quarrying & Aggregates – Ideal for.

Learn More