With 30+ years of expertise, we engineer crushing systems that maximize your productivity

while minimizing operational costs through smart, sustainable designs.

Applications

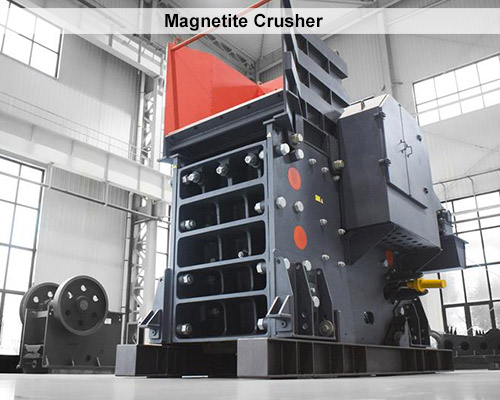

Magnetite Crusher

1. Magnetite Mining Overview

Magnetite, a key iron ore, requires robust crushing equipment to extract and process its hard, abrasive particles. Efficient crushing ensures optimal beneficiation and steel production.

2. Magnetite Crushing Equipment by Liming Heavy Industry

Primary Crushing: C6X/Jaw Crusher Series

- C6X Jaw Crusher: Handles large magnetite lumps (≤1,200mm) with high crushing efficiency, ideal for primary reduction.

- PE Jaw Crusher: Cost-effective for medium-hardness magnetite, featuring simple structure and low maintenance.

Secondary Crushing: Hydraulic Cone Crushers

- HPT Multi-cylinder Hydraulic Cone Crusher: Processes magnetite to 6–38mm with automatic crushing gap adjustment, reducing over-crushing.

- HST Single-cylinder Hydraulic Cone Crusher: Compact design for fine crushing (10–25mm output) with low energy consumption.

Tertiary Crushing: CI5X Impact Crusher

- Produces cubical, well-graded magnetite sand (0–5mm) for pelletizing, minimizing downstream grinding costs.

3. Supporting Equipment

- S5X Vibrating Screen: Precisely separates crushed magnetite into desired sizes.

- VSI6X Sand Maker: Enhures particle shape for high-grade iron concentrate.

4. Why Choose Liming Heavy Industry?

- Proven Models: C6X, HPT, CI5X, etc., widely used in global magnetite projects.

- Customizable Lines: From 50–3,000 TPH, tailored to ore hardness and output demands.

- Durability: Wear-resistant materials like Mn steel extend crusher lifespan in abrasive magnetite crushing.

From primary PE crushers to precision HPT cone crushers, Liming Heavy Industry ensures optimal magnetite size reduction. Contact us for tailored crushing solutions!

Custom Crushing Solutions For All

Mining & Aggregates Needs

Get Your Free Solution Quote Our Products

Key Equipment

C5X Jaw Crusher

Mining & Ore Processing Ideal for primary crushing of iron ore, gold ore, copper ore, and other metallic/non-metallic minerals. Handles tough materials.

Learn More

C6X Jaw Crusher

Mining & Metallurgy Primary crushing of iron ore, copper ore, gold ore, and other metallic/non-metallic minerals. Aggregate Production Ideal for producing high-quality.

Learn More

HST Hydraulic Cone Crusher

The HST Hydraulic Cone Crusher is ideal for: Mining: Efficient crushing of ores (iron, copper, gold, etc.) Quarrying: Processing hard rocks (granite,.

Learn More

PEW Jaw Crusher

Mining: Ideal for primary crushing of hard ores (gold, iron, copper) and abrasive rocks. Quarrying: Efficiently processes granite, basalt, and other aggregates.

Learn More

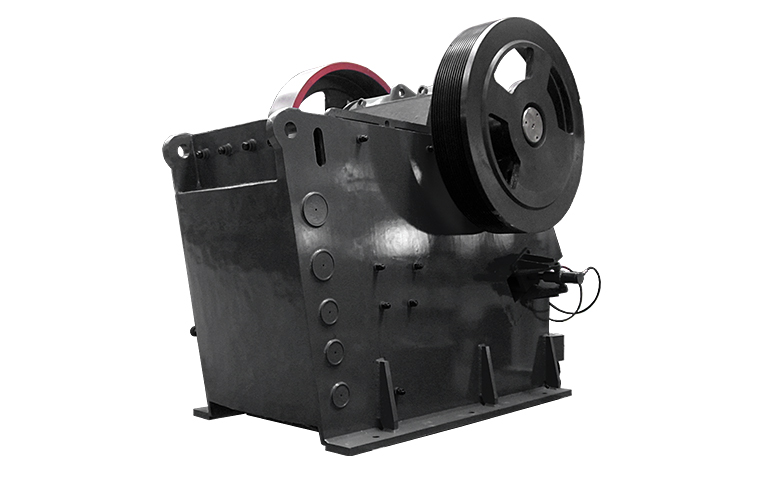

PE Jaw Crusher

Ideal for primary crushing of various materials: Mining/Ore Processing: Crushing gold, copper, iron ore, and manganese. Aggregates & Construction: Granite, basalt, limestone,.

Learn More

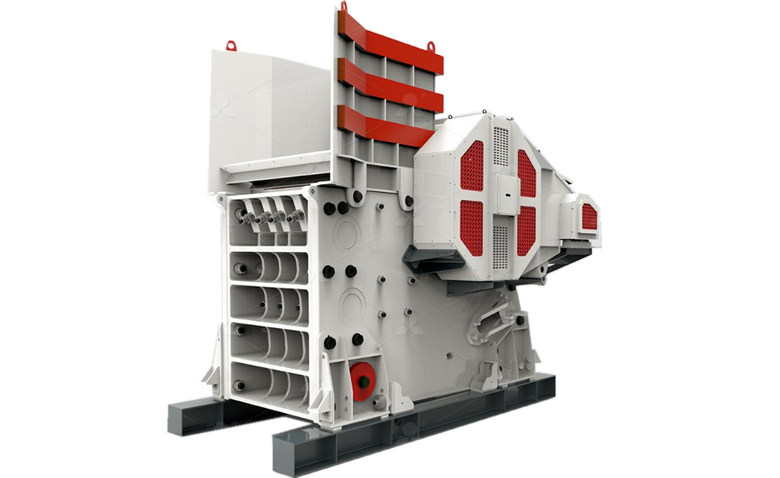

HPT Hydraulic Cone Crusher

Mining & Quarrying: Crushing hard rocks (granite, basalt, iron ore) with high reduction ratios. Aggregate Production: Producing cubic-shaped end products for construction.

Learn More