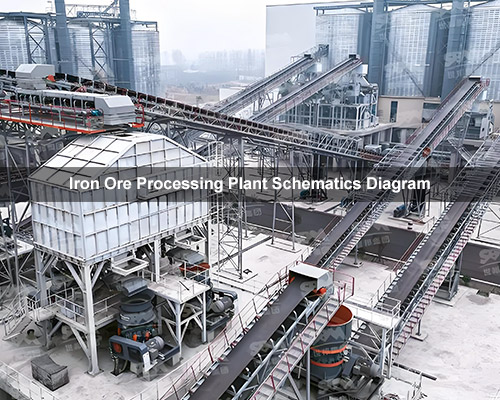

In the competitive global mining sector, efficiency is the cornerstone of profitability. For investors and mine operators, understanding the iron ore processing plant schematics diagram is not just about knowing where machines go—it’s about visualizing the flow of value. At Liming Heavy Industry, we understand that traditional processing lines often suffer from high wear rates, inconsistent particle sizes, and excessive energy consumption. This article provides a comprehensive breakdown of an optimized processing flow designed to solve these industry pain points using our state-of-the-art technology.

1. Analyzing Iron Ore Characteristics and Processing Challenges

Before designing a schematic, we must understand the material. Iron ore (commonly Magnetite, Hematite, or Limonite) typically presents a Mohs hardness of 5.5 to 6.5, with significant abrasiveness.

Industry Pain Points:

- High Equipment Wear: Abrasive ores rapidly degrade liners in inferior crushers.

- Low Recovery Rates: Poor crushing ratios lead to over-grinding, wasting valuable fines.

- Energy Inefficiency: Outdated plant designs consume excessive electricity per ton.

The Liming Solution: By utilizing a multi-stage crushing and screening circuit depicted in our advanced schematics, we ensure a “more crushing, less grinding” approach, significantly reducing operational costs.

2. Deep Dive: The Iron Ore Processing Plant Schematics Diagram

A typical high-efficiency production line designed by Liming Heavy Industry follows a logical progression: Crushing, Screening, Grinding, and Beneficiation. Here is the breakdown of the core equipment modules.

Phase 1: Primary Crushing

Raw iron ore is fed into the primary crusher via a GZD Series Vibrating Feeder. The standard choice for this stage is the PE Series Jaw Crusher.

The PE Series Jaw Crusher features a deep crushing cavity and no dead zone, which improves the feeding capacity and output quantity. It handles large boulders and reduces them to a manageable size (e.g., <150mm) for the secondary stage.

Phase 2: Secondary & Fine Crushing

This is critical for the iron ore processing plant schematics diagram. The output from the jaw crusher is conveyed to the secondary crusher. For hard iron ore, we recommend the HST Single Cylinder Hydraulic Cone Crusher or the HPT Multi-Cylinder Hydraulic Cone Crusher.

- HST Cone Crusher: Utilizing a unique inter-particle crushing action, the HST series produces a more uniform cubic product, which reduces the load on the subsequent grinding phase. Its automated control system allows for real-time monitoring.

Phase 3: Screening and Closed-Circuit Loop

Material flows to the YZS Vibrating Screen. Ores that meet the size requirement enter the grinding mill, while oversized stones are returned to the Cone Crusher for re-crushing. This closed-circuit design ensures strict particle size control.

3. Technical Specifications: Selecting the Right Liming Equipment

Choosing the correct model depends on your capacity requirements. Below is a comparison of our popular models used in iron ore plants.

| Equipment Type | Recommended Model | Max Feed Size (mm) | Capacity (t/h) | Key Advantage |

|---|---|---|---|---|

| Primary Crusher | PE-900×1200 | 750 | 220 – 450 | High stability, classic durable design. |

| Primary Crusher (High Capacity) | C6X125 | 800 | 280 – 650 | European style, bolt-fastened structure (no welding). |

| Secondary Crusher | HST160 | 260 (Coarse cavity) | 120 – 425 | Fully automatic hydraulic control, high efficiency. |

| Fine Crusher | HPT300 | 230 | 160 – 480 | Multi-cylinder technology for finer output. |

4. Application Case Study: 300TPH Iron Ore Line in Southeast Asia

Liming Heavy Industry recently commissioned a complete plant for a client dealing with hard Hematite.

- Challenge: The client required a schematic that minimized slime generation to improve magnetic separation efficiency.

- Solution: We implemented a configuration of PE-900×1200 Jaw Crusher + HPT300 Cone Crusher + YZS2460 Vibrating Screen.

- Result: The plant achieved a stable output of 320 tons per hour. The cubic shape of the final product improved the efficiency of the downstream ball mill by 15%, significantly shortening the payback period.

5. Installation and Maintenance Guide

To ensure your iron ore processing plant schematics diagram translates into reality, proper maintenance is non-negotiable.

- Foundation: Ensure a reinforced concrete foundation to absorb the vibration of heavy machinery like the PE Jaw Crusher.

- Lubrication: For HST Cone Crushers, regularly check the hydraulic station and lubrication oil temperature. Use the specified oil grade tailored to the ambient temperature.

- Wear Parts: Monitor the wear of the jaw plates and mantle/concave. Liming provides high-manganese steel parts designed for extended life.

6. Buying Guide: How to Source the Best Equipment

When procuring equipment for your iron ore plant, consider the following:

- Verify the Manufacturer: Ensure you are dealing with the original manufacturer like Liming Heavy Industry to guarantee genuine parts and service.

- Analyze Material Reports: Submit your raw ore samples. We customize the cavity type of the Cone Crusher based on your ore’s hardness.

- After-Sales Support: Check for availability of local engineers for installation and training.

7. Frequently Asked Questions (Q&A)

Q1: Can Liming provide a customized iron ore processing plant schematics diagram?

A: Yes, our engineers design custom flowcharts based on your specific terrain, capacity, and final product size requirements.

Q2: Why choose the HST Cone Crusher over a standard spring cone crusher?

A: The HST Series uses hydraulic pressure to adjust the discharge opening and clear the cavity, offering higher automation, efficiency, and easier maintenance than traditional spring models.

Q3: What is the typical lead time for a complete crushing plant?

A: Generally, production takes 30-45 days. However, popular models like the PE-600×900 or HPT300 are often in stock.

Q4: Does the schematic include the beneficiation part?

A: While we focus on crushing and screening, we can integrate magnetic separators and flotation cells into the schematic to offer a turnkey solution.

Q5: How do you handle shipping for such heavy equipment?

A: Liming Heavy Industry has extensive experience in logistics. We disassemble large units like the C6X Jaw Crusher into modular parts for container shipping and reassemble them on-site.

An optimized iron ore processing plant schematics diagram is the blueprint for a successful mining operation. By leveraging Liming Heavy Industry’s advanced PE Series Jaw Crushers and Hydraulic Cone Crushers, you invest in reliability, efficiency, and superior product quality. Don’t let inefficient designs eat into your profits.