As a leading manufacturer of crushing and screening equipment, including stone crushers, mining crushers, and mineral processing equipment, Liming Heavy Industry is committed to providing reliable solutions for global customers. In this article, we delve into the jaw crusher structural diagram to help you understand the inner workings of this essential machinery. Whether you’re involved in mining, construction, or aggregate production, comprehending the schematic diagram of jaw crusher can optimize your operations and equipment selection.

What is a Jaw Crusher Structural Diagram?

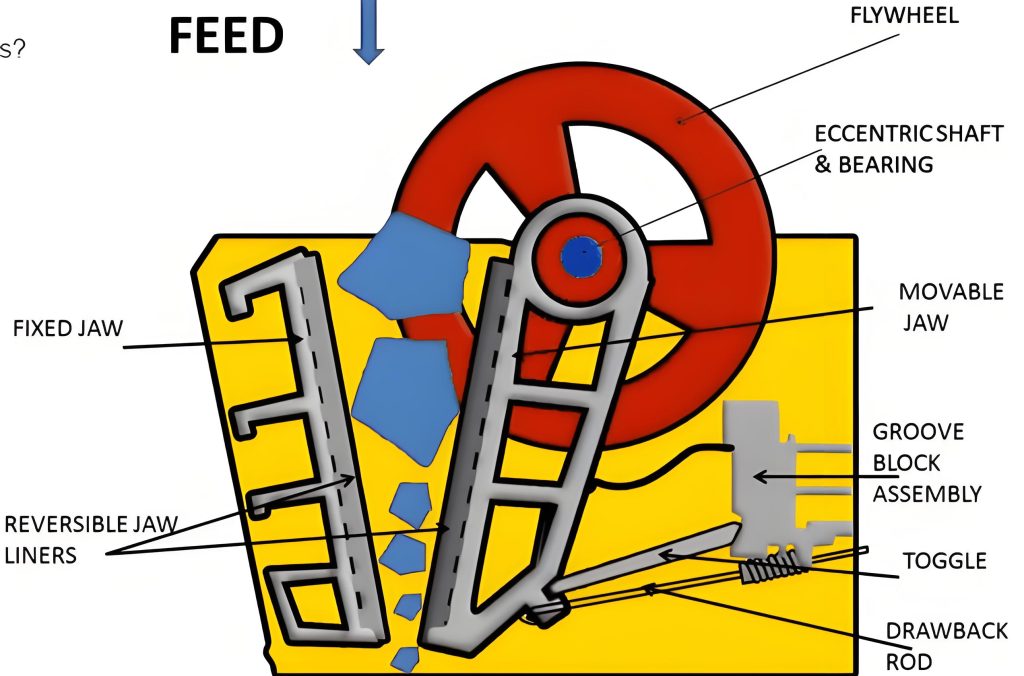

A jaw crusher structural diagram is a visual representation that outlines the key components and assembly of a jaw crusher. It serves as a blueprint for engineers, operators, and maintenance teams, illustrating how parts like the frame, jaw plates, eccentric shaft, and toggle plate interact. At Liming Heavy Industry, we emphasize the importance of these diagrams in our product documentation for models such as the PE-500×750 and PE-600×900 jaw crushers. By studying the schematic diagram of jaw crusher, customers can better grasp the machine’s durability and efficiency, leading to informed decisions in their projects.

Key Components in a Jaw Crusher Structural Diagram

The jaw crusher structural diagram typically includes several critical elements that ensure smooth operation. Here’s a breakdown of the main parts:

- Frame: The robust foundation that houses all components, designed for stability under heavy loads. In our PE series crushers, like the PE-500×750, the frame is engineered from high-strength steel to withstand harsh mining conditions.

- Jaw Plates: These are the crushing surfaces that come into direct contact with materials. Made from manganese steel in Liming Heavy Industry models, they offer exceptional wear resistance.

- Eccentric Shaft: This component drives the movable jaw, creating the crushing motion. A well-designed schematic diagram of jaw crusher highlights its role in reducing energy consumption and enhancing productivity.

- Toggle Plate: Acts as a safety mechanism to protect the crusher from overloads. In our JC series jaw crushers, this part is optimized for easy replacement, minimizing downtime.

By referring to a jaw crusher structural diagram, operators can perform routine maintenance more effectively, extending the lifespan of equipment like our PE-600×900 model.

Benefits of Understanding Jaw Crusher Diagrams for Customers

For customers in industries such as mining and construction, analyzing the schematic diagram of jaw crusher offers practical advantages. It enables better troubleshooting, reduces operational costs, and ensures compatibility with other machinery like vibrating screens and ball mills from Liming Heavy Industry. For instance, our PE-500×750 jaw crusher features a user-friendly design that aligns with diagrams for easy assembly and disassembly. This understanding helps in selecting the right model for specific applications, whether it’s primary crushing in quarry operations or secondary processing in mineral beneficiation.

Liming Heavy Industry’s Jaw Crusher Models and Their Structural Design

At Liming Heavy Industry, we integrate advanced engineering into our jaw crushers, as reflected in their structural diagrams. Our popular models include:

- PE-500×750 Jaw Crusher: Ideal for medium-scale crushing, this model features a simple yet robust structure detailed in its jaw crusher structural diagram. It offers a feed opening of 500×750 mm and is known for high efficiency and low maintenance.

- PE-600×900 Jaw Crusher: Designed for larger operations, this crusher has a feed size of 600×900 mm and incorporates elements like reinforced frames and adjustable jaw plates, as shown in the schematic diagram of jaw crusher. It ensures reliable performance in tough environments.

These models are part of our comprehensive range of crushing equipment, which also includes impact crushers, cone crushers, and vibrating screens. By leveraging detailed diagrams, we help customers achieve optimal crushing ratios and throughput.

Conclusion

In summary, the jaw crusher structural diagram and schematic diagram of jaw crusher are invaluable tools for anyone involved in material processing. At Liming Heavy Industry, we prioritize clarity in our technical documentation to support your success. If you’re looking for durable and efficient jaw crushers like the PE-500×750 or PE-600×900, our expertise ensures you get equipment tailored to your needs. For more information, explore our product offerings and discover how our solutions can enhance your operations.