Projects

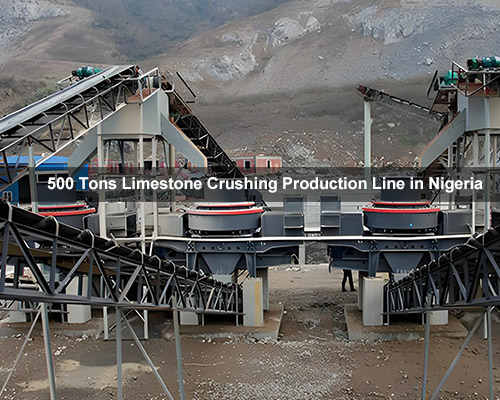

500 Tons Limestone Crushing Production Line in Nigeria

Client Overview

A leading construction materials supplier in Nigeria sought to establish a high-capacity limestone crushing and sand production plant to meet booming infrastructure demands. The project aimed to produce 500 tons per hour of high-quality aggregates and manufactured sand for road construction and concrete production.

Project Overview

- Location: Nigeria

- Material: Limestone (compressive strength: 120–150MPa)

- Feed Size: ≤750mm

- Output Requirements:

- 0–5mm (sand) – 30%

- 5–20mm – 40%

- 20–31.5mm – 30%

- Capacity: 500TPH

- Project Duration: 6 months (from design to commissioning)

Challenges

- High Abrasiveness: Limestone wear demands durable equipment.

- Strict Gradation: Needed precise control over aggregate/sand ratios.

- Dust Control: Compliance with Nigeria’s environmental regulations.

- Energy Efficiency: Client prioritized low-operating-cost solutions.

Solution: Customized Crushing Line by Liming Heavy Industry

1. Primary Crushing – C6X Jaw Crusher

- Model: C6X160

- Role: Coarse crushing of ≤750mm limestone lumps.

- Advantages:

- Integral cast steel structure for high fatigue resistance.

- 15–20% lower energy consumption vs. conventional crushers.

- Adjustable hydraulic wedge system for quick discharge setting changes.

2. Secondary Crushing – HPT Hydraulic Cone Crusher

- Model: HPT300

- Role: Medium/fine crushing to produce 20–31.5mm aggregates.

- Advantages:

- Multi-cylinder design ensures stable output gradation.

- Laminated crushing principle reduces wear costs by 30%.

- PLC automation adjusts crushing parameters dynamically.

3. Tertiary Shaping & Sand Making – VSI6X Sand Maker

- Model: VSI6X1263

- Role: Producing 0–5mm high-quality sand with cubical shape.

- Advantages:

- Four-port impeller design boosts throughput by 20%.

- Patented “rock-on-rock” crushing minimizes metal contamination.

- Modular wear parts extend maintenance cycles to 400+ hours.

4. Auxiliary Equipment

- Vibrating Feeder: ZSW490×130 (pre-screening to remove fines)

- Circular Vibrating Screen: 3YK3072 (3-deck classification)

- Dust Collector: Pulse-jet baghouse system (dust emission <20mg/m³)

Technical Highlights

Smart Control System: Centralized PLC monitors production data in real time.

Low Wear Costs: High-chrome blow bars & mantles extend service life.

Turnkey Delivery: Liming provided foundation design, installation supervision, and operator training.

Project Results

Output Achieved: Stable 510TPH (exceeding target by 2%).

Product Quality:

- Sand fineness modulus: 2.6–2.8 (ideal for concrete).

- Aggregate flakiness index: <10%.

Environmental Compliance: Fully enclosed design with noise <75dB.

ROI: Client recovered investment within 14 months.

Client Feedback

“Liming’s team delivered exceptional expertise—from equipment selection to on-site training. The VSI6X sand maker’s low maintenance and high yield transformed our profitability. We’re planning a second 800TPH line with Liming.”

— Project Manager, Nigerian Client

Custom Crushing Solutions For All

Mining & Aggregates Needs

while minimizing operational costs through smart, sustainable designs.