Projects

Ethiopia 200 TPH Limestone Crushing Plant

Client Brief

A leading construction material supplier in Ethiopia sought a reliable limestone crushing solution to produce high-quality sand and aggregates for local infrastructure projects. With strict requirements for output size, capacity (200TPH), and durability, they partnered with Liming Heavy Industry for expert machinery and a customized solution.

Project Overview

Material: Limestone

Input Size: ≤750mm

Output Size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm (sand & aggregates)

Capacity: 200 tons per hour

Location: Ethiopia

Application: Road construction, concrete production

Challenges

- High abrasiveness of limestone required wear-resistant equipment.

- Tight gradation control for multi-grade aggregates.

- Need for energy-efficient, low-maintenance machinery suited to Ethiopia’s rugged conditions.

Solution: Customized Crushing Line by Liming Heavy Industry

1. Primary Crushing – C6X Jaw Crusher

- Model: C6X145

- Role: Coarse crushing of raw limestone (≤750mm → ≤300mm).

- Advantages: High crushing ratio, modular design for easy maintenance, durable cast steel frame.

2. Secondary Crushing – HPT Hydraulic Cone Crusher

- Model: HPT300

- Role: Further reduces material to ≤60mm for aggregate shaping.

- Advantages: Multi-cylinder hydraulic system ensures stable output and overload protection.

3. Tertiary Crushing – VSI6X Sand Maker

- Model: VSI6X1263

- Role: Produces 0-5mm high-quality sand with excellent cubical shape.

- Advantages: Low wear costs, optimized rotor design for higher sand yield.

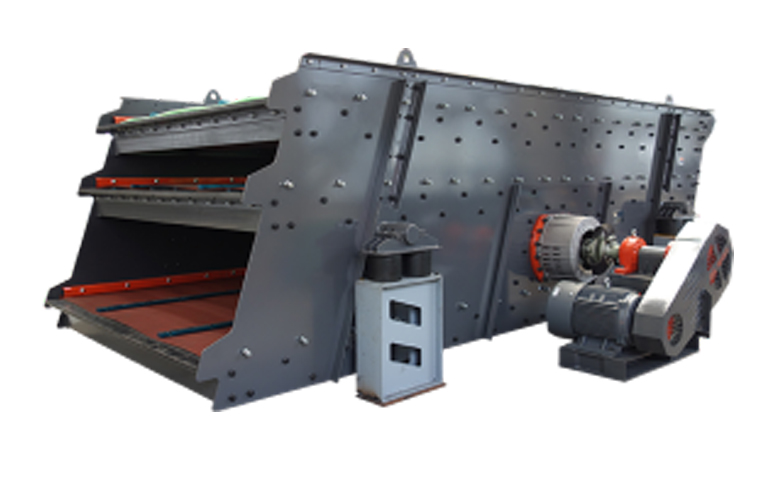

4. Screening – S5X Vibrating Screen

- Model: S5X2460-2

- Role: Separates final products into 4 precise specifications.

- Advantages: Dual-motor drive for efficient screening in high-load conditions.

Supporting Equipment:

- Belt conveyors (B6X series) for seamless material transfer.

- Dust removal system compliant with environmental standards.

Technical Highlights

- Smart Control System: Automated process monitoring reduces manual intervention.

- Energy Savings: HPT cone crusher and VSI6X sand maker optimize power consumption.

- Longevity: Anti-wear components extend equipment lifespan in abrasive limestone crushing.

Project Results

- Achieved 200TPH steady output with 90% uptime.

- Sand & aggregates met EN/BS standards for construction use.

- Reduced operational costs by 30% compared to traditional solutions.

Client Feedback

“Liming’s team delivered a turnkey solution tailored to our needs. The C6X jaw crusher and VSI6X sand maker exceeded our expectations in productivity and durability. We’re confident in expanding our collaboration!”

— Project Manager, Ethiopia Client

Custom Crushing Solutions For All

Mining & Aggregates Needs

while minimizing operational costs through smart, sustainable designs.

Key Equipment

S5X Vibrating Screen

VSI6X Sand Making Machine

C6X Jaw Crusher