Copper extraction from its ore is a complex process that involves several stages of physical and chemical processing. As a leading manufacturer of mining and processing equipment, Liming Heavy Industry provides advanced machinery for efficient copper extraction. This article explains the copper extraction process and how our equipment can optimize your operations.

The Copper Extraction Process: From Ore to Pure Metal

Copper extraction typically involves three main stages: mining, concentration, and purification. The specific methods vary depending on the ore type and composition, but generally follow these steps:

1. Mining Copper Ore

Copper can be extracted from both open-pit and underground mines. The choice of mining method depends on the ore grade, depth, and geological characteristics. Once extracted, the ore is transported to processing plants for further treatment.

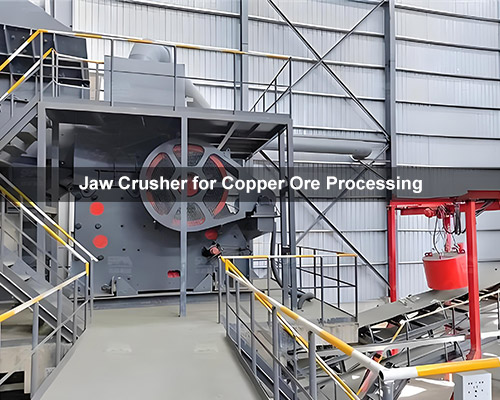

2. Crushing and Grinding

The first step in processing copper ore is crushing and grinding. Large chunks of ore are reduced to smaller pieces using jaw crusher, then further ground into fine powder in ball mills or grinding mills. This increases the surface area for subsequent chemical processing.

3. Concentration by Froth Flotation

Most copper ores undergo froth flotation to separate copper minerals from gangue (waste material). In this process, the ground ore is mixed with water and reagents, then agitated. Copper particles attach to air bubbles and rise to the surface, forming a froth that is skimmed off.

4. Smelting and Refining

The concentrated copper ore (now called concentrate) is smelted in furnaces at high temperatures to remove impurities. This produces matte copper, which is further refined through electrolysis or other methods to produce high-purity copper cathodes (99.99% pure).

5. Environmental Considerations

Modern copper extraction processes prioritize environmental protection through waste management, water recycling, and emission control systems. Liming Heavy Industry designs equipment with these considerations in mind.

Request Quotation for Copper Processing Equipment

Liming Heavy Industry (Henan Liming Heavy Industry Science & Technology Co., Ltd.) offers comprehensive solutions for copper extraction, including:

- Jaw crushers and cone crushers for primary and secondary crushing

- Ball mills and grinding mills for ore grinding

- Flotation machines for concentration

- Complete processing plant design and installation

Our equipment is designed for high efficiency, reliability, and minimal environmental impact. We provide customized solutions based on your specific ore characteristics and production requirements.

Why Choose Liming Heavy Industry?

With over 30 years of experience in mining equipment manufacturing, we offer:

- Advanced technology and innovative designs

- High-quality, durable machinery

- Competitive pricing

- Comprehensive after-sales service

- Global installation and support network

For a detailed quotation on copper processing equipment, please contact our sales team with your specific requirements, including production capacity, ore characteristics, and any other relevant details.