Copper, one of humanity’s most essential metals, plays a critical role in electrical wiring, plumbing, renewable energy systems, and countless industrial applications. The journey from raw copper-bearing ore to refined copper products involves a sophisticated extraction and processing methodology requiring specialized equipment and expertise. As a leading manufacturer of mineral processing equipment, Liming Heavy Industry provides advanced solutions for copper extraction operations worldwide. This comprehensive guide examines the complete process drawing of copper extraction and processing, highlighting key technologies, equipment capabilities, and innovative approaches to optimizing recovery rates and operational efficiency.

Copper Ore Characteristics and Material Introduction

Copper ores primarily exist as sulfide ores (such as chalcopyrite, chalcocite, and bornite) and oxide ores (like malachite and azurite). These ores typically contain between 0.5% and 2% copper, mixed with various gangue minerals. The mineral composition, dissemination characteristics, and hardness significantly influence the selection of processing methods and equipment. Sulfide ores are generally processed through conventional crushing, grinding, and flotation techniques, while oxide ores often require alternative approaches like acid leaching, solvent extraction, and electrowinning. Understanding the specific properties of the copper ore is essential for designing an efficient processing circuit and selecting appropriate equipment for each stage of operation.

Equipment Application Range in Copper Processing

Modern copper processing plants utilize a range of specialized equipment designed to handle the specific requirements of copper ore beneficiation. At Liming Heavy Industry, we manufacture a complete portfolio of processing equipment capable of handling all stages of copper extraction:

- Crushing Equipment: Jaw crushers, cone crushers, and impact crushers for primary, secondary, and tertiary crushing applications

- Grinding Equipment: Ball mills, rod mills, and SAG mills for reducing crushed ore to fine particles

- Separation Equipment: Flotation machines, magnetic separators, and thickening equipment

- Material Handling Equipment: Vibrating feeders, belt conveyors, and bucket elevators

- Ancillary Systems: Dust collection, water treatment, and automation control systems

Our equipment is engineered to handle the abrasive nature of copper ores and the demanding conditions of mineral processing operations, ensuring reliable performance and minimized downtime.

Equipment Technology and Innovation

At Liming Heavy Industry, we continuously integrate advanced technologies into our copper processing equipment to enhance efficiency, reduce operating costs, and improve recovery rates. Our technological innovations include:

Intelligent Crushing Systems

Our latest jaw crushers and cone crushers feature advanced control systems that automatically adjust the crusher settings in real-time based on feed conditions and product requirements. This intelligent automation ensures optimal crushing efficiency, reduces power consumption, and minimizes wear part costs.

Energy-Efficient Grinding Technology

Our ball mills and grinding systems incorporate innovative liner designs and drive systems that reduce energy consumption by up to 30% compared to conventional designs. The optimized grinding chamber geometry ensures better media distribution and more effective size reduction.

Advanced Flotation Technology

We offer cutting-edge flotation equipment with improved bubble generation mechanisms and residence time distribution, enhancing mineral recovery rates. Our automated reagent dosing systems precisely control chemical addition based on ore grade variations, optimizing reagent consumption.

Integrated Process Control

Our equipment can be integrated with plant-wide process control systems that monitor and optimize the entire copper extraction process from crushing to concentration. These systems use advanced algorithms to maximize throughput while maintaining product quality specifications.

Equipment Capacity and Types for Copper Processing

Selecting equipment with appropriate capacity and specifications is crucial for designing an efficient copper processing plant. Liming Heavy Industry offers a comprehensive range of equipment types and sizes to match various production requirements:

| Processing Stage | Equipment Type | Model Examples | Capacity Range | Key Features |

|---|---|---|---|---|

| Primary Crushing | Jaw Crusher | PE1200×1500, PE900×1200 | 300-800 t/h | Deep crushing chamber, high reduction ratio, rugged construction |

| Secondary Crushing | Cone Crusher | HST315, HPT500 | 200-700 t/h | Hydraulic adjustment, automatic control system, high capacity |

| Tertiary Crushing | Multi-Cylinder Hydraulic Cone Crusher | HPT300, HPT400 | 100-450 t/h | Fine crushing capability, excellent product shape, low wear costs |

| Grinding | Ball Mill | MQG2700×3600, MQG3200×4500 | 10-200 t/h | Optimized length-to-diameter ratio, efficient grinding media classification |

| Classification | Hydrocyclone | FX350-GT, FX500-GT | According to plant size | Precise separation, wear-resistant construction, minimal maintenance |

| Flotation | Flotation Machine | BF-20, XJK-8 | Variable | Efficient aeration, low energy consumption, optimized froth handling |

Copper Ore Crushing Process Flow

The copper ore crushing process typically follows a three-stage closed-circuit system, which is considered the modern standard for high-hardness copper ore crushing. This approach maximizes reduction efficiency while minimizing energy consumption:

1. Primary Crushing

Run-of-mine copper ore (typically up to 1000mm in size) is fed into primary jaw crusher using vibrating feeders. Our PE1200×1500 and PE900×1200 jaw crushers are commonly used for this stage, reducing the ore to 150-300mm particles :cite[3]. These crushers feature deep crushing chambers and high reduction ratios, making them ideal for handling large, abrasive copper ores.

2. Secondary Crushing

The crushed material from the primary stage is conveyed to secondary cone crusher, such as our HST315 or HPT500 models. These crushers further reduce the ore size to 50-100mm. Our cone crushers incorporate hydraulic adjustment systems and advanced crushing chamber designs that ensure consistent product size distribution and high capacity.

3. Tertiary Crushing

For final size reduction before grinding, tertiary cone crushers (like our HPT300 and HPT400 models) are employed in closed circuit with vibrating screens. This stage produces ore particles typically smaller than 12-20mm. The use of multi-cylinder hydraulic cone crushers in this stage ensures excellent particle shape and size distribution, which improves downstream grinding efficiency.

The crushing process follows the “more crushing, less grinding” principle, which significantly reduces overall energy consumption by minimizing the amount of material that requires energy-intensive grinding.

Common Challenges and Solutions in Copper Processing

Copper processing operations face several challenges that can impact productivity, recovery rates, and operating costs. Based on our extensive experience, we’ve developed effective solutions for these common issues:

Variable Ore Hardness and Abrasiveness

Challenge: Fluctuations in ore hardness can lead to unexpected equipment wear and reduced throughput. Solution: Our crushers feature wear-resistant materials and innovative liner designs that extend service life. Additionally, our automated control systems can adjust crusher parameters in real-time to accommodate changing feed conditions.

Achieving Target Grind Size Efficiently

Challenge: Obtaining the optimal particle size for liberation without overgrinding. Solution: Our grinding circuits incorporate advanced classification systems that ensure precise size control. The use of hydrocyclones and vibrating screens in closed-circuit grinding operations helps maintain optimal grind size while maximizing throughput.

Maintaining High Recovery Rates with Variable Ore Grades

Challenge: Fluctuating copper content in the feed ore affects flotation performance. Solution: Our advanced process control systems continuously monitor ore grade and adjust reagent dosing and flotation parameters accordingly, maintaining optimal recovery rates across varying feed conditions.

Water Management and Environmental Compliance

Challenge: Managing water usage and tailings disposal in an environmentally responsible manner. Solution: We offer advanced water recycling systems and tailings management solutions, including high-rate thickeners and filter presses for dry stacking, significantly reducing environmental impact.

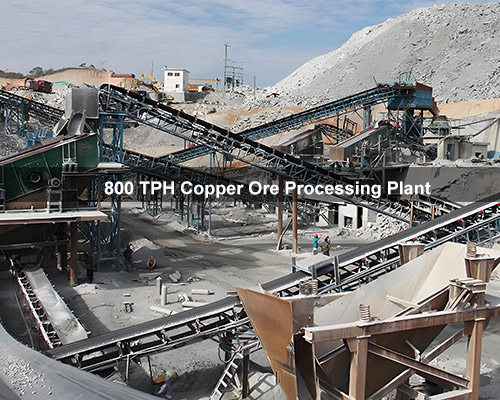

Case Study: 800 TPH Copper Processing Plant Modernization

Project Overview

A major copper producer in South America partnered with Liming Heavy Industry to modernize their existing processing facility. The project aimed to increase throughput from 600 to 800 tons per hour while reducing energy consumption and operating costs.

Equipment Supplied

- Primary Crushing: PE1200×1500 Jaw Crusher

- Secondary Crushing: Two HST315 Cone Crushers

- Tertiary Crushing: HPT500 Multi-cylinder Hydraulic Cone Crusher

- Screening: 2YKR3675N Double-layer Vibrating Screen

- Grinding: MQG3200×4500 Ball Mill with classification circuit

Results Achieved

The modernization project delivered significant improvements in operational efficiency:

- Throughput increased from 600 to 800 TPH (33% increase)

- Overall energy consumption reduced by 15%

- Crushing circuit product size reduced from 25mm to 19mm

- Grinding circuit media consumption decreased by 33%

- Overall copper recovery improved from 89.2% to 92.2%

Why Choose Liming Heavy Industry for Copper Processing Solutions

Selecting the right equipment supplier is critical for the success of any copper processing operation. Here’s why leading mining companies worldwide trust Liming Heavy Industry:

Comprehensive Product Portfolio

We offer a complete range of equipment for copper processing, from primary crushing to concentration, ensuring seamless integration and optimized performance across the entire circuit.

Proven Technology and Expertise

With over 30 years of experience in mineral processing equipment manufacturing, we have developed deep expertise in copper extraction technologies and process optimization.

Energy-Efficient Solutions

Our equipment is designed with energy efficiency as a priority, incorporating features that reduce power consumption while maintaining high throughput and recovery rates.

Global Support Network

We maintain a comprehensive support network with service centers and spare parts facilities strategically located around the world, ensuring prompt technical support and minimal downtime.

Customized Solutions

We understand that each copper deposit has unique characteristics, and we work closely with clients to develop customized solutions that address their specific processing challenges.

Conclusion

Copper extraction and processing is a complex operation that requires carefully designed process flows and high-performance equipment to achieve optimal recovery rates and economic viability. The process drawing of copper extraction involves multiple stages, from primary crushing of run-of-mine ore to concentration through flotation or hydrometallurgical methods. Each stage presents unique challenges that require robust, efficient equipment specifically designed for copper processing applications.

Liming Heavy Industry offers a comprehensive portfolio of processing equipment, including advanced jaw crushers, cone crushers, grinding mills, and separation systems, all engineered to deliver reliable performance in demanding copper processing operations. Our focus on technological innovation, energy efficiency, and process optimization ensures that our clients achieve the highest possible returns on their investment.

For mining companies seeking to improve existing operations or develop new copper processing facilities, partnering with an experienced equipment supplier with proven technology and industry expertise is essential for long-term success. With our comprehensive product range and deep industry knowledge, Liming Heavy Industry is ideally positioned to support your copper processing requirements and help you achieve your production and profitability goals.